- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Cutting-edge Automation: Crafting Excellence with Pasta Production Line's Efficiency

Cutting-edge Automation: Crafting Excellence with Pasta Production Line's Efficiency

Cutting-edge Automation: Crafting Excellence with Pasta Production Line's Efficiency

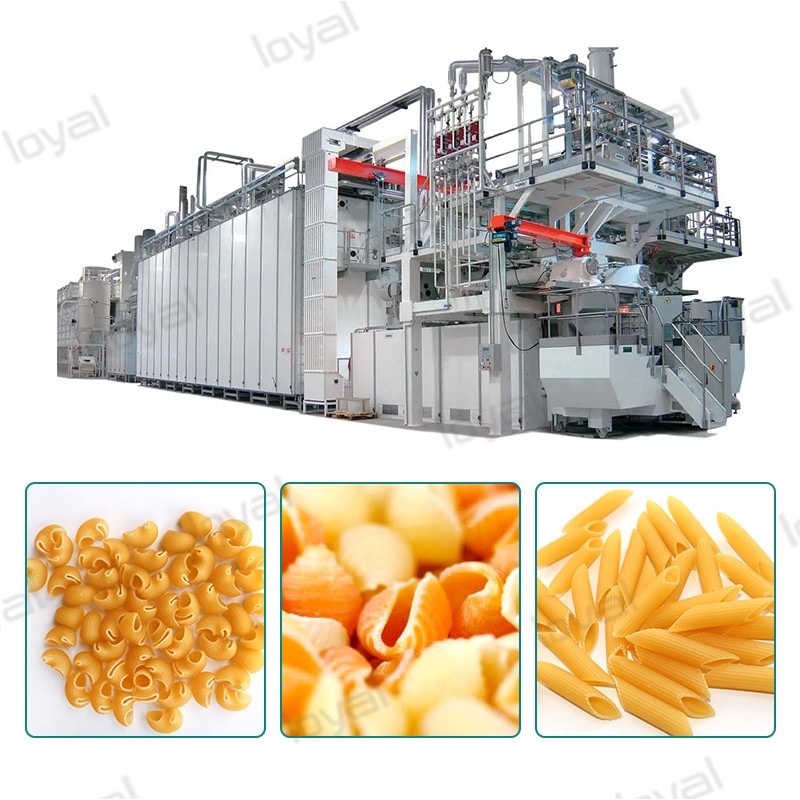

In the modern landscape of macaroni pasta production line, the integration of automation has become a pivotal force, transforming traditional methods into a realm of cutting-edge efficiency. This introduction sets the stage for exploring the evolution and impact of automation in pasta production.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from BID and PDominioni in the production of its macaroni.

Precision and quality stand as the cornerstones of excellence in pasta manufacturing. This section delves into the intricacies of crafting exceptional pasta and introduces the Pasta Production Line as a key player in achieving and maintaining this level of quality.

Efficiency is more than just a buzzword; it's a driving force behind cost-effectiveness, heightened quality, and sustainable practices. This part establishes the direct link between automation and the efficiency that defines the modern Pasta Production Line.

The Core Components of Cutting-edge Automation

The heartbeat of cutting-edge automation lies in the state-of-the-art machinery integrated into the Pasta Production Line. This segment explores the advanced components that contribute to the creation of high-quality pasta, emphasizing precision and technological excellence.

Smart technologies, including Artificial Intelligence (AI) and the Internet of Things (IoT), are not just buzzwords but integral parts of the Pasta Production Line. We delve into how these technologies enhance precision, control, and overall efficiency in the manufacturing process.

Automation isn't just about replacing manual labor; it's about optimizing every step of the pasta production process. This section discusses how the Pasta Production Line's processes are fine-tuned for excellence, ensuring consistency and quality at every stage.

Achieving Excellence: Benefits of Automation

Consistency is a mark of quality. Here, we explore how automation in the Pasta Production Line leads to consistent quality across batches, meeting and exceeding consumer expectations for taste and texture.

Efficiency gains aren't just theoretical; they are quantifiable improvements in production speed and capacity. This part delves into the positive impact of automation on the efficiency of the Pasta Production Line, showcasing tangible results.

Beyond the immediate benefits, automation contributes to broader environmental sustainability. We examine how efficient processes within the Pasta Production Line reduce environmental impact and discuss the incorporation of energy-saving features.

Case Studies: Success Stories in Crafting Excellence

In this section, we present compelling case studies of prominent pasta manufacturers who have wholeheartedly embraced cutting-edge automation. These industry leaders, including Barilla, De Cecco, Creamette, and San Giorgio, serve as exemplars of success in achieving excellence and efficiency through the adoption of advanced technologies.

Moving beyond anecdotes, we delve into quantifiable results observed by companies that have adopted automation in their Pasta Production Lines. By providing data-driven insights, we showcase how these manufacturers have achieved tangible benefits in terms of production optimization, cost-effectiveness, and elevated product quality.

Future Trends and Innovations in Pasta Production

The future of pasta production is shaped by continuous technological advancements. This section explores the latest innovations that will influence the Pasta Production Line, covering areas such as machinery, connectivity, and sustainability. We anticipate and discuss the transformative impact of emerging technologies on the industry.

Looking beyond the present, we project the trajectory of the pasta production industry. By discussing ongoing innovations, we provide insights into how the Pasta Production Line will evolve, adapt, and further refine its efficiency. The road ahead involves a dynamic interplay of technology, sustainability, and consumer preferences.

Conclusion

This section serves as a comprehensive recapitulation of the profound impact of cutting-edge automation on pasta manufacturing. We revisit key points, emphasizing how the Pasta Production Line, through automation, has played a pivotal role in crafting excellence in the industry.

The concluding remarks underscore the dynamic nature of the pasta production industry. We emphasize the need for a proactive approach in embracing future technologies to sustain and enhance excellence. The Pasta Production Line stands at the forefront of this evolution, continually shaping the landscape of pasta manufacturing.

FAQs: Frequently Asked Questions about Pasta Production Line

In this section, we address common queries related to the Pasta Production Line, providing insightful answers that cater to the interests of manufacturers, industry professionals, and consumers.

1. How does automation impact the quality of pasta produced by the Pasta Production Line?

Automation significantly enhances the quality of pasta produced. The precision and consistency achieved through automated processes ensure that each batch meets the highest standards, satisfying consumer expectations for taste and texture.

2. Are there notable pasta manufacturers using cutting-edge automation in their production lines?

Certainly. Industry leaders such as Barilla, De Cecco, Creamette, and San Giorgio have embraced cutting-edge automation in their Pasta Production Lines. These manufacturers serve as benchmarks for success in achieving excellence and efficiency through advanced technologies.

3. What quantifiable benefits can be expected from adopting automation in Pasta Production Lines?

Companies adopting automation experience quantifiable benefits, including increased production efficiency, reduced operational costs, and elevated product quality. The data-driven insights reveal tangible results, showcasing the positive impact on overall production optimization.

4. How does the Pasta Production Line contribute to environmental sustainability?

The Pasta Production Line, through its efficient processes and incorporation of energy-saving features, contributes to environmental sustainability. By minimizing resource consumption and reducing waste, automated systems align with broader goals of eco-friendly and sustainable manufacturing practices.

5. What emerging technologies are likely to shape the future of Pasta Production Lines?

Emerging technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and sustainable machinery advancements are expected to shape the future of Pasta Production Lines. These innovations will further optimize processes, enhance connectivity, and promote sustainability within the industry.

6. How can pasta manufacturers prepare for the evolving landscape of the industry?

Pasta manufacturers can prepare for the evolving landscape by staying informed about emerging technologies, fostering adaptability, and proactively embracing innovations. The dynamic nature of the industry necessitates a forward-thinking approach to ensure continued success and excellence.

7. Is there a balance between automation and traditional craftsmanship in pasta production?

While automation plays a crucial role in ensuring efficiency and consistency, traditional craftsmanship still holds significance in certain aspects of pasta production. The balance between the two allows manufacturers to preserve artisanal quality while benefiting from the advancements offered by automation.

8. What role do consumer preferences play in shaping the future of Pasta Production Lines?

Consumer preferences are instrumental in shaping the future of Pasta Production Lines. Manufacturers need to be attuned to evolving consumer demands, including preferences for sustainable practices, quality ingredients, and diverse pasta varieties. Adapting to these preferences ensures continued relevance and success in the market.

9. How can Pasta Production Lines contribute to global sustainability goals?

Pasta Production Lines contribute to global sustainability goals by minimizing environmental impact, optimizing resource utilization, and embracing energy-efficient practices. The industry's commitment to sustainable production aligns with broader initiatives aimed at fostering a more environmentally responsible and resilient future.

10. In conclusion, what is the key takeaway regarding Pasta Production Line's impact on the industry?

The key takeaway is that the Pasta Production Line, driven by cutting-edge automation, has redefined the industry's standards for excellence, efficiency, and sustainability. Embracing innovation, adapting to consumer preferences, and staying ahead of technological advancements are essential for manufacturers looking to thrive in the ever-evolving landscape of pasta production

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

VACUUM PASTA EXTRUDER

VACUUM PASTA EXTRUDER Combined Pasta Production Line

Combined Pasta Production Line Long-Cut Pasta Production Line

Long-Cut Pasta Production Line Spaghetti Pasta Production Line

Spaghetti Pasta Production Line