- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Elevate Your Production with the Full-Automatic Macaroni Making Machine: Efficient and Energy-Saving

Elevate Your Production with the Full-Automatic Macaroni Making Machine: Efficient and Energy-Saving

Elevate Your Production with the Full-Automatic Macaroni Making Machine: Efficient and Energy-Saving

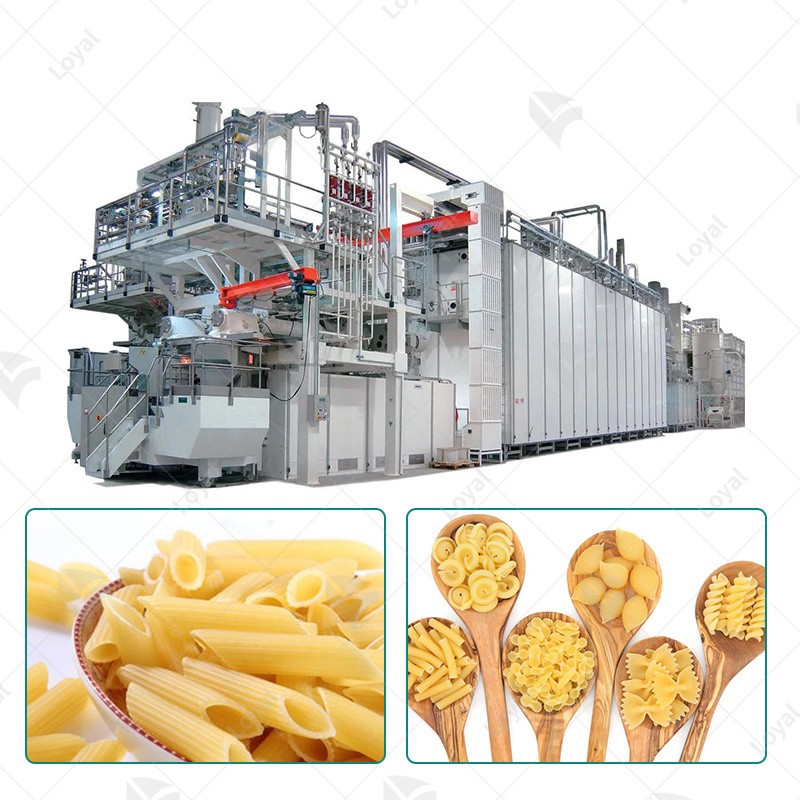

The world of macaroni production is evolving, and at the forefront of this transformation is the Full-Automatic Macaroni Pasta Production Line. As demand for high-quality macaroni products continues to rise, manufacturers are seeking innovative solutions to enhance production efficiency. This article explores the profound impact of the Full-Automatic Macaroni Making Machine on the food machinery industry, focusing on its efficiency and energy-saving features.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from FAVA and UTF in the production of its macaroni

Features of the Full-Automatic Macaroni Making Machine

The heart of this revolutionary machine lies in its advanced automation technology. By seamlessly integrating cutting-edge features, such as automated mixing, kneading, and shaping processes, it elevates macaroni production to new heights. The machine's ability to precisely control each stage of production ensures consistent quality and reduces the margin of error.

In addition to its automation prowess, the Full-Automatic Macaroni Making Machine is designed to enhance overall production efficiency. It incorporates intelligent systems that optimize raw material usage, reduce downtime, and minimize waste. Manufacturers can now achieve higher output without compromising on the quality of their macaroni products.

Energy-Saving Mechanisms

One of the standout features of this macaroni making machine is its commitment to energy efficiency. The detailed discussion in this section delves into the machine's energy-efficient design, highlighting how it minimizes power consumption throughout the production process. By utilizing state-of-the-art energy-saving mechanisms, the Full-Automatic Macaroni Making Machine not only benefits the environment but also significantly reduces operational costs for manufacturers.

A comparative analysis with traditional macaroni making processes underscores the machine's superiority in terms of energy conservation. Industry experts commend the shift towards sustainable practices, and the Full-Automatic Macaroni Making Machine stands as a beacon of progress in this regard.

Operational Efficiency

This section showcases real-world examples of the Full-Automatic Macaroni Making Machine in action, highlighting its operational efficiency and the resulting impact on overall production. Through case studies, manufacturers can gain valuable insights into how adopting this technology can lead to increased productivity and a more streamlined workflow.

The operational efficiency extends beyond speed and output; it encompasses the machine's ability to adapt to different macaroni shapes and sizes with minimal adjustments. This flexibility opens up new possibilities for manufacturers to diversify their product offerings.

Technological Advancements

The Full-Automatic Macaroni Making Machine incorporates cutting-edge technologies that set it apart from conventional pasta production equipment. This section examines these technological advancements, providing insights into how they contribute to a more efficient and streamlined production process.

Experts in the field praise the integration of smart sensors, precision control systems, and data analytics, emphasizing how these technologies enhance the reliability and consistency of macaroni production. The machine's user-friendly interface also ensures ease of operation and maintenance.

Industry Impact

An in-depth analysis of how the Full-Automatic Macaroni Making Machine is reshaping the macaroni production industry forms the core of this section. With a focus on the potential benefits for manufacturers and the market as a whole, the article explores the machine's role in driving innovation and setting new industry standards.

Quotes from industry leaders and authoritative figures highlight the significance of adopting such advanced technology in staying competitive and meeting the evolving demands of consumers. The ripple effect on market dynamics and consumer choices is evident, positioning the Full-Automatic Macaroni Making Machine as a game-changer.

Conclusion

In summary, the Full-Automatic Macaroni Making Machine stands as a beacon of innovation in the macaroni production landscape. The article recaps key points regarding efficiency and energy savings, emphasizing the transformative role this machine plays in shaping the future of macaroni manufacturing. As manufacturers increasingly prioritize sustainability and efficiency, the Full-Automatic Macaroni Making Machine emerges as a crucial asset in meeting these objectives.

FAQs: Common Questions about Macaroni Making Machines

1. What makes the Full-Automatic Macaroni Making Machine different from traditional pasta machines?

- The Full-Automatic Macaroni Making Machine sets itself apart through advanced automation technology. Unlike traditional pasta machines, it seamlessly integrates automated processes, optimizing efficiency and ensuring consistent product quality.

2. How does the Full-Automatic Macaroni Making Machine contribute to energy savings?

- The machine's energy-saving mechanisms involve a meticulous design that minimizes power consumption throughout the production process. From intelligent systems optimizing raw material usage to sustainable practices, the Full-Automatic Macaroni Making Machine significantly reduces operational costs and environmental impact.

3. Can the machine handle different types and sizes of macaroni products?

- Yes, one of the remarkable features of the Full-Automatic Macaroni Making Machine is its operational flexibility. It can adapt to various macaroni shapes and sizes with minimal adjustments, offering manufacturers the ability to diversify their product range easily.

4. What technological advancements are incorporated into the Full-Automatic Macaroni Making Machine?

- The machine leverages cutting-edge technologies, including smart sensors, precision control systems, and data analytics. These advancements enhance reliability, consistency, and ease of operation. The user-friendly interface ensures that even operators with minimal experience can efficiently manage the machine.

5. How is the Full-Automatic Macaroni Making Machine impacting the pasta production industry?

- The machine is reshaping the pasta production industry by setting new standards for efficiency and innovation. Industry leaders recognize its transformative impact, emphasizing the need for manufacturers to adopt advanced technology to stay competitive and meet evolving consumer demands.

6. Are there notable brands using the Full-Automatic Macaroni Making Machine in their production processes?

- Several renowned brands, including Barilla, De Cecco, Creamette, San Giorgio, and Great Value, have embraced the Full-Automatic Macaroni Making Machine. This reflects the machine's credibility and reliability, as these industry-leading brands prioritize cutting-edge technology for their pasta production.

7. What are the benefits of adopting the Full-Automatic Macaroni Making Machine for manufacturers?

- Manufacturers enjoy increased productivity, consistent product quality, and reduced operational costs. The machine's efficiency and energy-saving features contribute to a positive environmental impact, aligning with modern sustainability goals and consumer preferences.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

PRECOOKED PASTA PRODUCTION LINE

PRECOOKED PASTA PRODUCTION LINE Long-Cut Pasta Production Line

Long-Cut Pasta Production Line Pasta Processing Equipment

Pasta Processing Equipment Instant Pasta Production Line

Instant Pasta Production Line