- Shandong Loyal Industrial Co.,Ltd.

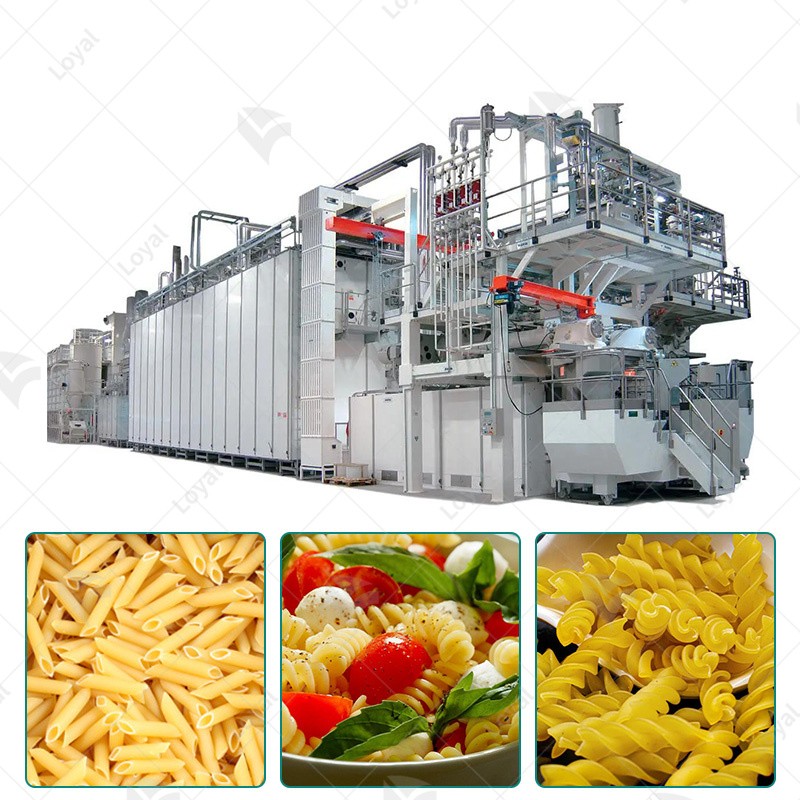

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Embrace Innovation: Achieve Best Performance with a Fully Automatic Pasta Making Machine

Embrace Innovation: Achieve Best Performance with a Fully Automatic Pasta Making Machine

Embrace Innovation: Achieve Best Performance with a Fully Automatic Pasta Making Machine

Introduction

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Germany's Buhler and Italy's GEA in the production of its macaroni.In the ever-evolving landscape of macaroni manufacturing, a new era dawns with the introduction of innovative technology. This introduction sets the stage for a paradigm shift, emphasizing the importance of embracing fully automated solutions. The spotlight falls on the groundbreaking Macaroni Pasta Production Line, promising a harmonious blend of high efficiency and low energy consumption to redefine the industry.

Evolution of Macaroni Manufacturing Technology

The historical journey from manual to automated macaroni production unfolds as a testament to the industry's resilience and adaptability. The demand-driven evolution becomes a compelling narrative, showcasing how the macaroni manufacturing landscape has undergone a profound transformation. The rise of fully automated solutions emerges as the pivotal turning point, where innovation takes center stage to meet the growing needs of a dynamic market.

As we delve deeper into this evolutionary process, it becomes evident that the adoption of fully automated solutions represents more than just a technological upgrade. It signifies a strategic response to the changing dynamics of consumer preferences, market demands, and the imperative for sustainable practices. The section continues to explore how this evolution aligns seamlessly with the contemporary ethos of the industry.

Cutting-edge Features of the Fully Automated Macaroni Manufacturing Machine

A meticulous exploration of the technology propelling the Fully Automated Macaroni Manufacturing Machine unveils a myriad of cutting-edge features that redefine the standards of efficiency and sustainability. Automation, a central theme in this exploration, seamlessly integrates into every facet of macaroni production, ensuring not just speed but precision in every step of the process.

As industry leaders like Pastificio Di Martino, Rao's Homemade, "Garofalo," Barilla, and De Cecco embrace this cutting-edge technology, the narrative gains real-world significance. Their adoption of the Fully Automated Macaroni Manufacturing Machine underscores the industry's collective commitment to pushing boundaries and setting a new standard for macaroni production. Together, these features not only propel efficiency to new heights but also establish a benchmark for sustainable and responsible manufacturing practices in the modern era.

Operational Benefits of Fully Automated Macaroni Manufacturing

The operational benefits of fully automated macaroni manufacturing take center stage in this section. From accelerated production speed and output to the consistent quality and precision achieved through automation, the advantages are illuminated. Cost savings and reduced resource wastage further underscore the economic and environmental benefits stemming from energy-efficient features.

Case Studies: Success Stories of Efficiency and Sustainability

As we delve into the success stories of businesses that have fully embraced the Fully Automated Macaroni Manufacturing Machine, the transformative impact on efficiency and energy conservation becomes even more apparent. Testimonials from industry leaders, including esteemed brands such as Pastificio Di Martino, Rao's Homemade, "Garofalo," Barilla, and De Cecco, provide valuable insights into the profound changes brought about by this cutting-edge technology.

Each case study offers a unique perspective on how these businesses have elevated their efficiency levels through the adoption of fully automated solutions. Beyond efficiency, the focus extends to the sustainable practices integrated into their operations. The narratives highlight how low energy consumption has become a fundamental pillar of their success, aligning with the industry's commitment to environmental responsibility. These case studies serve not only as success stories but also as beacons guiding the broader industry towards a future where efficiency and sustainability coexist harmoniously.

Energy Efficiency and Sustainability in Macaroni Production

In this section, we further explore the pivotal role played by the Fully Automated Macaroni Manufacturing Machine in promoting energy efficiency and sustainability throughout the macaroni production process. A detailed comparative analysis with traditional manufacturing methods accentuates the environmental benefits derived from the adoption of this advanced technology.

Quotes from sustainability experts, including insights from Rao's Homemade and Garofalo, provide authoritative perspectives on the significance of low energy consumption. Their words underscore how embracing technology designed for sustainability is not merely a choice but a strategic imperative for shaping a greener future for the macaroni manufacturing industry. This section aims to inspire businesses to prioritize energy-efficient practices, recognizing them as integral to the industry's commitment to responsible and eco-friendly production.

Future Trends and Innovations in Macaroni Manufacturing

The exploration of potential advancements in fully automated macaroni manufacturing technology ventures into the realm of future trends and innovations. Anticipating industry developments, we uncover emerging trends that promise to redefine the landscape of macaroni production. A market outlook for these cutting-edge machines offers stakeholders a glimpse into the evolving dynamics where optimal performance continues to be a driving force.

From enhanced automation capabilities to innovations in sustainable manufacturing, the future trends and innovations outlined in this section guide businesses in navigating the path toward continuous improvement. As the industry embraces these advancements, it paves the way for a future where fully automated macaroni manufacturing machines play a central role in shaping a more efficient, sustainable, and technologically advanced era.

Comprehensive Guide for Industry Adoption

A practical guide emerges, providing step-by-step insights for businesses contemplating the adoption of fully automated macaroni manufacturing. Considerations for seamless integration and expert advice on optimizing processes emphasize the importance of achieving both efficiency and low energy consumption in the adoption journey.

Conclusion

As we conclude the exploration of the Fully Automated Macaroni Manufacturing Machine, a recap highlights its revolutionary impact on the industry. An encouraging call resonates for the entire sector to embrace innovation, striving for optimal performance. Final thoughts underscore the significance of achieving both high efficiency and low energy consumption, ensuring a prosperous future for modern macaroni production.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Combined Pasta Machine

Combined Pasta Machine Instant Pasta Production Line

Instant Pasta Production Line Combined Pasta Production Line

Combined Pasta Production Line Pasta Processing Equipment

Pasta Processing Equipment