- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Enhancing Efficiency: Full Automation in Spaghetti Pasta Production Line Equipment

Enhancing Efficiency: Full Automation in Spaghetti Pasta Production Line Equipment

Enhancing Efficiency: Full Automation in Spaghetti Pasta Production Line Equipment

Unveiling the Imperative of Enhancing Efficiency in Spaghetti Pasta Production

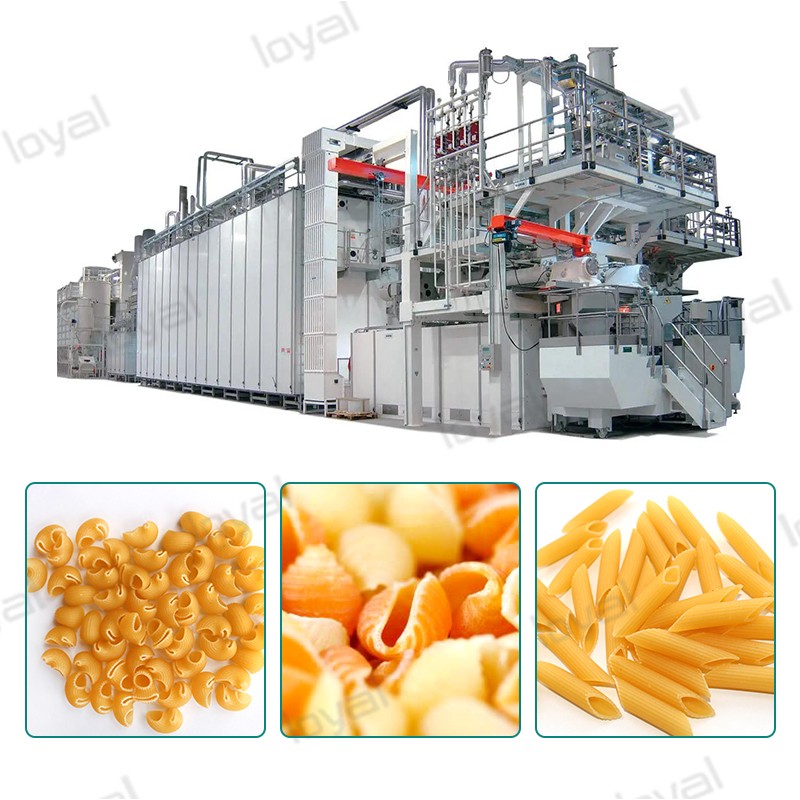

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from SARP and FEN in the production of its macaroni.In the ever-evolving landscape of food manufacturing, the quest for efficiency is paramount. This introduction sets the stage for exploring how the paradigm shift towards full automation in spaghetti pasta production line equipment becomes an imperative for enhancing efficiency. As consumer demands rise and competition intensifies, understanding the evolution of spaghetti production lines becomes essential for manufacturers seeking a competitive edge.

Evolution of Spaghetti Pasta Production Lines: The Paradigm Shift Towards Full Automation

Tracing the historical evolution of spaghetti pasta production lines reveals a significant paradigm shift towards full automation. From manual processes to semi-automated systems, the narrative unfolds, showcasing the pivotal role of technology in streamlining production. Quotes from industry experts emphasize the transformative nature of this shift and its direct impact on efficiency and productivity.

The Essence of Full Automation in Spaghetti Pasta Production Line Equipment

This section delves into the essence of full automation, defining it as the comprehensive integration of technology to perform all aspects of spaghetti production. The pivotal role that full automation plays in enhancing efficiency becomes evident as we explore how it streamlines processes, minimizes errors, and optimizes resource utilization. Expert opinions highlight the significance of adopting full automation in the competitive spaghetti manufacturing landscape.

Key Advantages of Implementing Full Automation in Spaghetti Pasta Production Equipment

Enumerating the key advantages of implementing full automation in spaghetti pasta production equipment solidifies the argument for its adoption. From increased production speed to enhanced product consistency, each advantage is presented with supporting data and insights. Real-world examples further illustrate how manufacturers stand to benefit from the efficiency gains brought about by fully automated systems.

Cutting-edge Technologies: Features of Fully Automated Spaghetti Pasta Production Line Equipment

This section explores the cutting-edge technologies that define fully automated spaghetti pasta production line equipment. Precision engineering takes center stage, ensuring unparalleled consistency and quality in spaghetti production. From advanced sensors to robotic systems, the emphasis is on how these technologies contribute to the precision required for producing high-quality pasta products. Quotes from industry leaders underscore the importance of precision in today's competitive market.

In addition to precision, this part highlights the energy-efficient features embedded in fully automated spaghetti pasta production line equipment. Sustainability is a key focus, and the article examines how manufacturers are incorporating eco-friendly practices into their processes. Insights from environmental experts and industry pioneers shed light on the sustainable technological solutions that contribute to both operational efficiency and environmental responsibility.

Integrating Full Automation into Spaghetti Pasta Manufacturing Processes

This section provides practical guidance on implementing full automation into spaghetti pasta manufacturing processes. From initial planning to the integration phase, manufacturers can learn effective strategies for a seamless transition. Expert advice from consultants and engineers offers valuable insights into overcoming challenges and maximizing the efficiency gains associated with full automation.

Measurable Improvements: Enhancing Production Efficiency and Output through Advanced Automation

Building upon the implementation strategies, this part explores the measurable improvements that result from the adoption of full automation. Manufacturers can expect enhanced production efficiency, increased output, and reduced operational costs. Statistical data and case studies provide concrete evidence of the positive impact on overall business performance. Testimonials from industry leaders reinforce the transformative outcomes achievable through advanced automation.

Innovations in Full Automation for Spaghetti Pasta Production Equipment

This section explores the latest innovations driving the evolution of fully automated spaghetti pasta production line equipment. Technological advancements, such as artificial intelligence and machine learning, play a pivotal role in shaping the future of automated systems. Interviews with technology experts shed light on the ongoing developments that are reshaping the landscape of spaghetti production.

In addition to technological advancements, a focus on innovations aligned with sustainability goals takes center stage. The article delves into how manufacturers are adopting eco-friendly materials, energy-efficient processes, and waste reduction strategies. These innovations not only contribute to environmental sustainability but also align with the growing consumer demand for ethically produced food products.

Success Stories: Pasta Manufacturers Thriving with Fully Automated Equipment

Highlighting success stories, this section features real-world examples of pasta manufacturers thriving with fully automated equipment. Case studies from prominent companies demonstrate the transformative impact of adopting full automation on various aspects of production. Testimonials from industry leaders and the measurable benefits achieved provide tangible evidence of the positive outcomes.

Tangible Benefits and Achievements Through the Adoption of Fully Automated Systems

The focus shifts to the tangible benefits and achievements realized by pasta manufacturers through the adoption of fully automated systems. From increased production capacity to improved product quality, each benefit is presented with supporting evidence. This section aims to inspire other manufacturers to consider the adoption of full automation for their spaghetti production lines.

The Next Frontier: Emerging Trends in Fully Automated Systems

Looking towards the future, this section explores anticipated developments in fully automated spaghetti pasta production technology. Emerging trends, such as the integration of smart technologies and Industry 4.0 principles, are discussed. Industry experts provide insights into what the next frontier holds for fully automated systems, paving the way for manufacturers to stay ahead in a rapidly evolving market.

Sustainable Practices and the Ongoing Evolution of Spaghetti Pasta Production Technology

Sustainability remains a key theme as the article delves into sustainable practices and the ongoing evolution of spaghetti pasta production technology. From eco-friendly materials to circular production processes, manufacturers are exploring ways to reduce their environmental footprint. Interviews with sustainability experts shed light on how these practices align with global sustainability goals.

Frequently Asked Questions about Spaghetti Pasta Production Line

Q1: How does full automation benefit spaghetti pasta manufacturers?

A: Full automation brings several benefits to spaghetti pasta manufacturers, including increased production efficiency, consistent product quality, reduced operational costs, and the ability to meet growing consumer demands. By automating various processes, manufacturers can streamline operations, minimize errors, and enhance overall productivity.

Q2: Are fully automated systems suitable for small-scale pasta production?

A: Yes, fully automated systems can be adapted for small-scale pasta production. Modular and scalable solutions are available, allowing manufacturers to tailor automation to their production volume. Small-scale producers can benefit from the efficiency gains, improved product consistency, and long-term cost savings offered by fully automated equipment.

Q3: How does sustainability play a role in fully automated spaghetti pasta production?

A: Sustainability is a crucial aspect of fully automated spaghetti pasta production. Innovations in eco-friendly materials, energy-efficient processes, and waste reduction strategies contribute to environmentally responsible manufacturing. By adopting sustainable practices, manufacturers not only reduce their environmental impact but also align with the preferences of environmentally conscious consumers.

Q4: What are the key considerations when implementing full automation in pasta production?

A: When implementing full automation, manufacturers should consider factors such as the scalability of the system, integration with existing processes, training requirements for personnel, and the potential for future upgrades. It's essential to conduct a thorough analysis of current operations to ensure a seamless transition to automated systems.

Q5: What emerging technologies are shaping the future of fully automated pasta production?

A: Emerging technologies shaping the future of fully automated pasta production include smart technologies, Internet of Things (IoT) integration, and advancements in artificial intelligence. These technologies enable predictive maintenance, real-time monitoring, and enhanced control over production processes, contributing to increased efficiency and reduced downtime.

Conclusion

The FAQs section provides valuable insights into common queries related to fully automated spaghetti pasta production lines. By addressing these questions, manufacturers can gain a deeper understanding of the benefits, suitability, sustainability aspects, key considerations, and emerging technologies associated with full automation in pasta production. This comprehensive overview aims to guide manufacturers in making informed decisions for the advancement of their production processes.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Instant Pasta Production Line

Instant Pasta Production Line Combined Pasta Production Line

Combined Pasta Production Line Combined Automatic Pasta Sheeter

Combined Automatic Pasta Sheeter DRY PASTA PRESS MACHINE

DRY PASTA PRESS MACHINE