- Shandong Loyal Industrial Co.,Ltd.

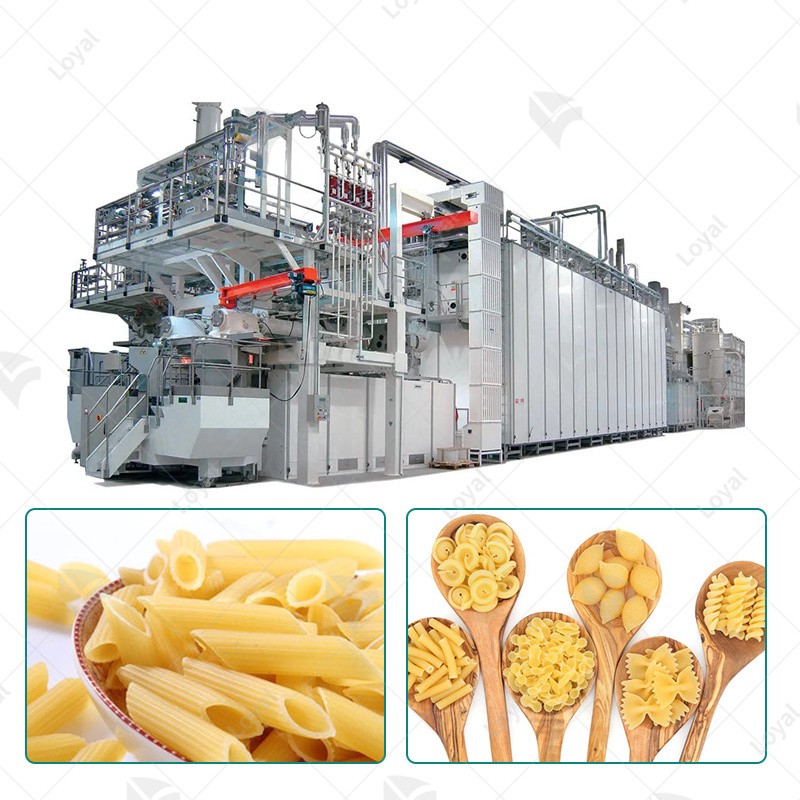

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Optimize Your Production Line: Full Automatic Solutions – The Shortcut for Manufacturing Pasta with High Efficiency and Energy Savings

Optimize Your Production Line: Full Automatic Solutions – The Shortcut for Manufacturing Pasta with High Efficiency and Energy Savings

Optimize Your Production Line: Full Automatic Solutions – The Shortcut for Manufacturing Pasta with High Efficiency and Energy Savings

In the ever-evolving realm of pasta production, the adoption of full automatic solutions as the shortcut for manufacturing has ushered in a new era of efficiency and energy savings. This introduction elucidates the significance of optimizing production lines through advanced technologies.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Tecalit and SARP in the production of its short-cut pasta production line.

Unveiling the Concept of Full Automatic Solutions

The concept of full automatic solutions in pasta manufacturing represents a paradigm shift, where intricate processes are seamlessly executed through automated systems. As we delve into this, it becomes apparent that the integration of automation is not just a technological upgrade but a strategic shortcut for achieving manufacturing excellence.

The Imperative of Efficiency and Energy Savings in Pasta Manufacturing

Efficiency and energy savings are not just desirable but imperative in the modern landscape of pasta manufacturing. This section explores the industry trends and challenges that make the adoption of the shortcut for manufacturing a strategic necessity in enhancing overall operational efficiency while prioritizing sustainability.

The Evolution of Pasta Production: Full Automatic Solutions

Historical Perspectives on Pasta Manufacturing

To comprehend the significance of full automatic solutions, a historical overview of pasta manufacturing is essential. From traditional methods to the mechanization that emerged during the Industrial Revolution, this section sets the stage for understanding how automation has evolved as a game-changer in the industry.

Integration of Full Automatic Solutions

The seamless integration of full automatic solutions into pasta production processes marks a pivotal moment in the industry's evolution. Technological advancements, from smart machinery to precision engineering, have redefined how pasta is manufactured. This section delves into the transformative impact of automation on shaping and improving production methods.

Key Components of Full Automatic Solutions

Automated Pasta Mixing and Kneading

Automated pasta mixing and kneading form the cornerstone of full automatic solutions. Precision in ingredient proportioning and real-time monitoring not only enhance the consistency of the product but also contribute to the overall efficiency of the production line. This section explores the intricacies of these automated processes.

Cutting-Edge Shaping and Forming Technologies

The advancement of cutting-edge shaping and forming technologies further solidifies the concept of a shortcut for manufacturing. From intricate pasta shapes to uniformity in size, this section delves into the technologies that streamline the shaping process, ensuring the final product meets the highest quality standards.

Benefits of Full Automatic Solutions: Efficiency and Energy Savings

Increased Production Output

The adoption of full automatic solutions translates to a significant increase in production output. Scalability and speed become achievable milestones, meeting the growing consumer demands for pasta products. This section emphasizes the quantitative improvements achieved by embracing automation.

Minimized Energy Consumption

Efficiency in pasta manufacturing goes hand in hand with minimized energy consumption. Full automatic solutions introduce sustainable practices, from energy-efficient drying processes to innovative packaging solutions. By minimizing the environmental footprint, manufacturers can achieve both cost-effectiveness and environmental responsibility.

Case Studies: Successful Implementation of Full Automatic Solutions

This section showcases industry leaders such as Colavita, Garofalo, Whole Foods 365 Everyday Value, Jovial, DeLallo, and Faella who have successfully implemented full automatic solutions. Their experiences serve as real-world examples of how embracing advanced technologies positively impacts production metrics.

Future Trends: Advancements in Full Automatic Solutions

As technology continues to advance, the future trends in full automatic solutions are explored in this section. From the integration of artificial intelligence to predictive maintenance, the article looks ahead at the innovations that will further enhance the efficiency and sustainability of pasta manufacturing.

Conclusion

In conclusion, the adoption of full automatic solutions as the shortcut for manufacturing pasta represents not just a technological advancement but a strategic move towards excellence. The industry has witnessed a transformative journey, and as we look ahead, the commitment to efficiency, energy savings, and sustainable practices will continue to drive the evolution of pasta production.

FAQs: Frequently Asked Questions about Shortcut for Manufacturing in Pasta Production

Curious minds often seek clarification on the concept of a shortcut for manufacturing in pasta production. Here, we address common queries to provide a comprehensive understanding of this innovative approach.

1. What defines a "shortcut for manufacturing" in the context of pasta production?

In the realm of pasta production, a shortcut for manufacturing refers to the strategic integration of full automatic solutions. This approach streamlines and automates various stages of the production line, from mixing and kneading to shaping and packaging, achieving efficiency and energy savings.

2. How do full automatic solutions contribute to efficiency in pasta production?

Full automatic solutions contribute to efficiency by eliminating manual interventions and optimizing processes. Automated pasta mixing, shaping, and packaging not only increase production output but also ensure precision and consistency, reducing the margin for errors and enhancing overall efficiency.

3. Are there specific challenges associated with implementing a shortcut for manufacturing in pasta production?

While the benefits are substantial, challenges in implementing a shortcut for manufacturing may include initial investment costs and the need for staff training. However, the long-term advantages, such as increased production efficiency and reduced operational costs, often outweigh these challenges.

4. Can smaller pasta manufacturers benefit from adopting full automatic solutions?

Absolutely. The flexibility of many full automatic solutions allows smaller pasta manufacturers to scale their operations according to their production capacity and goals. This adaptability ensures that even smaller players in the industry can benefit from the efficiency and energy savings offered by automation.

5. How do industry-leading brands such as Colavita, Garofalo, and Whole Foods 365 Everyday Value leverage full automatic solutions?

Leading brands leverage full automatic solutions to ensure consistency, quality, and efficiency in their pasta production. By embracing advanced technologies, these companies have increased production output, minimized energy consumption, and set benchmarks for the industry, showcasing the tangible benefits of the shortcut for manufacturing

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Instant Pasta Production Line

Instant Pasta Production Line DRY PASTA PRESS MACHINE

DRY PASTA PRESS MACHINE Dry Pasta Production Line

Dry Pasta Production Line PRECOOKED PASTA PRODUCTION LINE

PRECOOKED PASTA PRODUCTION LINE