- Shandong Loyal Industrial Co.,Ltd.

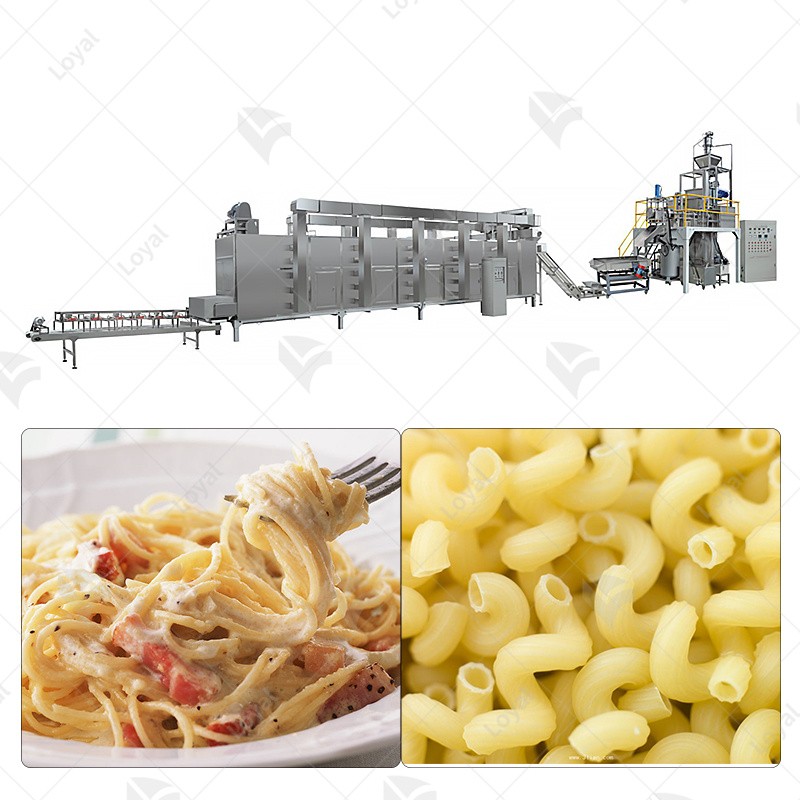

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Streamlining Excellence: The Ultimate in Full Automation with Linea Pasta Machine

Streamlining Excellence: The Ultimate in Full Automation with Linea Pasta Machine

Introduction

Pasta manufacturing has undergone a remarkable evolution throughout history, adapting to challenges and embracing modern opportunities. The emergence of Long-Cut Pasta Production Line marks a significant turning point, introducing full automation to streamline pasta production processes efficiently.

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from BUHLER and BID in the production of its macaroni.The historical journey of pasta production reveals a dynamic landscape, from traditional methods to the adoption of innovative technologies. Modern pasta manufacturing faces challenges that demand a sophisticated solution, setting the stage for the integration of Linea Pasta Machine.

As we delve into the emergence of Linea Pasta Machine, it becomes evident that this advanced system plays a pivotal role in revolutionizing pasta production. Full automation takes center stage, promising unparalleled efficiency in the manufacturing process.

Full Automation with Linea Pasta Machine

Full automation in pasta production represents a comprehensive approach that involves the seamless integration of advanced machinery and smart technologies. Linea Pasta Machine stands out as a key player in this realm, redefining the landscape with its cutting-edge features.

Linea Pasta Machine boasts state-of-the-art technology designed to optimize the pasta production line. From automated mixing to precision extrusion, Linea Pasta Machine leverages intelligent systems, ensuring a high level of efficiency and consistency.

Optimizing Efficiency in Pasta Production Line

Efficiency stands as a cornerstone in pasta production, influencing both output and quality. A detailed exploration of Linea Pasta Machine's role in streamlining the production line highlights the impact on enhancing efficiency and meeting consumer expectations.

Linea Pasta Machine goes beyond efficiency by incorporating energy-saving innovations. Examining these technologies provides insights into sustainable practices, with Linea Pasta Machine users successfully implementing initiatives to reduce environmental impact.

Case Studies: Linea Pasta Machine in Action

Real-world case studies showcase the success stories of pasta manufacturers implementing Linea Pasta Machine. These examples highlight the machine's positive impact on efficiency, quality, and overall production performance.

Linea Pasta Machine's adaptability to diverse production environments is explored through examining its integration in various settings. This section assesses the versatility of Linea Pasta Machine, illustrating its effectiveness in different pasta manufacturing scenarios.

Future Trends in Pasta Manufacturing with Linea Pasta Machine

A glimpse into the future reveals emerging technologies that will shape the landscape of pasta manufacturing. Linea Pasta Machine is positioned at the forefront, contributing to the ongoing technological advancements in automated pasta production.

Sustainability becomes a key focus in the evolving pasta manufacturing industry, with Linea Pasta Machine leading the way. This section delves into eco-friendly initiatives and practices implemented by Linea Pasta Machine users, aligning with global sustainability goals.

Conclusion

Linea Pasta Machine has played a crucial role in streamlining excellence in pasta manufacturing. This section recaps the key points discussed, emphasizing the machine's significance in achieving optimal efficiency.Looking ahead, Linea Pasta Machine sets the stage for the future of pasta manufacturing. The implications of full automation and advanced technology in the industry are discussed, providing insights into the continued evolution of pasta production practices.

In conclusion, Linea Pasta Machine stands as the ultimate solution for streamlining excellence in pasta manufacturing. Through full automation, cutting-edge technology, and a commitment to sustainability, Linea Pasta Machine not only meets the current demands of the industry but also shapes its future. As pasta manufacturers embrace this innovative solution, the implications for the industry are profound, ensuring a path of continued evolution and success.

FAQs: Frequently Asked Questions about Linea Pasta Machine

1. What is Linea Pasta Machine, and how does it revolutionize pasta production?

Linea Pasta Machine is an advanced pasta production system that leverages full automation for a streamlined process. Its technological features, from automated mixing to intelligent extrusion, mark a revolution in the efficiency and consistency of pasta production.

2. How does Linea Pasta Machine contribute to energy efficiency?

Linea Pasta Machine incorporates energy-saving innovations, reducing environmental impact. The machine's intelligent design and technology not only optimize efficiency but also align with sustainability goals, making it an eco-friendly choice for pasta manufacturers.

3. Can Linea Pasta Machine adapt to different pasta manufacturing environments?

Yes, Linea Pasta Machine demonstrates remarkable adaptability to various production settings. Case studies illustrate its successful integration in diverse environments, showcasing its versatility and effectiveness in different pasta manufacturing scenarios.

4. What are some notable achievements of Linea Pasta Machine in real-world implementations?

Real-world case studies highlight Linea Pasta Machine's positive impact on efficiency, quality, and overall production performance. Notable achievements include increased output, improved product consistency, and enhanced operational efficiency.

5. How does Linea Pasta Machine contribute to the future trends in pasta manufacturing?

Linea Pasta Machine plays a key role in shaping future trends by embracing emerging technologies. Its position at the forefront of technological advancements in automated pasta production positions it as a catalyst for ongoing industry evolution.

6. What sustainable practices are implemented by Linea Pasta Machine users?

Linea Pasta Machine users actively contribute to sustainability by implementing eco-friendly practices. From responsible sourcing of ingredients to energy-efficient manufacturing, these initiatives align with global sustainability goals and promote a greener pasta industry.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Pasta Processing Equipment

Pasta Processing Equipment Dry Pasta Production Line

Dry Pasta Production Line Combined Pasta Production Line

Combined Pasta Production Line Combined Automatic Pasta Sheeter

Combined Automatic Pasta Sheeter