- Shandong Loyal Industrial Co.,Ltd.

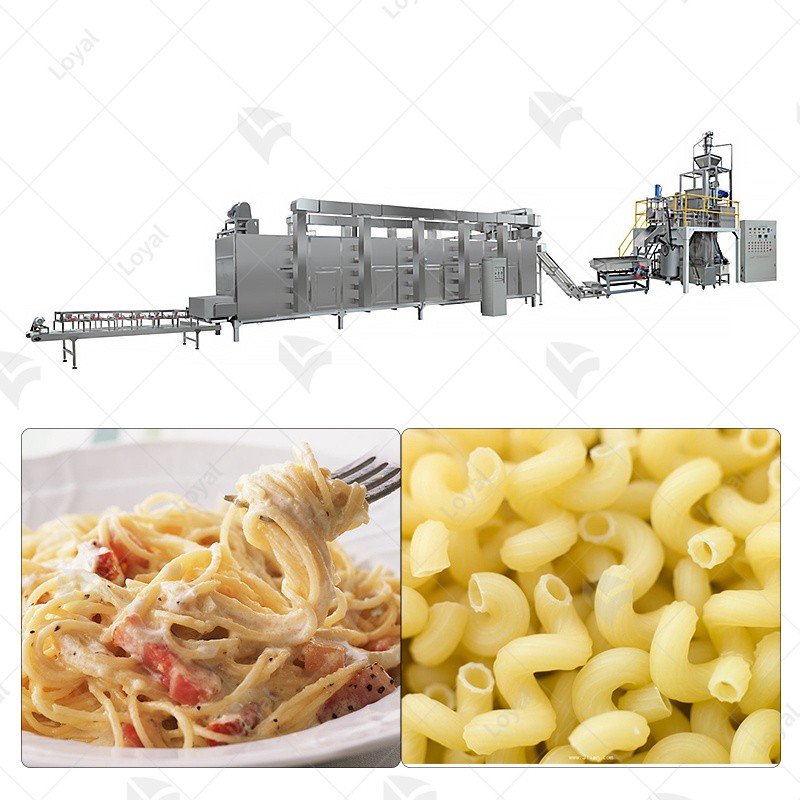

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> The Ultimate Guide To Unprecedented Spaghetti Pasta Production Line In 2024

The Ultimate Guide To Unprecedented Spaghetti Pasta Production Line In 2024

In recent years, the landscape of pasta production has witnessed unprecedented advancements, driven by cutting-edge technology. Among these innovations stands the Spaghetti Pasta Production Line—a revolutionary leap in the domain of food machinery. This article aims to delve into the intricacies of this groundbreaking production line, exploring its fully automatic and energy-efficient features and shedding light on its profound implications for the pasta manufacturing industry.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from FAVA and UTF in the production of its macaroni.

Fully Automatic Operation

The Spaghetti Pasta Production Line sets itself apart through its fully automated operation. Leveraging state-of-the-art robotics and artificial intelligence, this system streamlines the entire pasta production process. From mixing and kneading to extrusion and drying, every stage is seamlessly orchestrated without the need for manual intervention. This not only ensures precision and consistency in the quality of the pasta but also significantly reduces the reliance on human labor.

Energy-Efficient Design

An integral aspect of the Spaghetti Pasta Production Line is its energy-efficient design. Incorporating advanced technologies such as energy recovery systems and smart power management, this production line minimizes environmental impact while maximizing cost-effectiveness. The utilization of energy-efficient components not only aligns with sustainability goals but also proves to be economically advantageous for pasta manufacturers.

Technological Innovations

This section highlights the specific technological innovations embedded in the Spaghetti Pasta Production Line. Cutting-edge features such as real-time quality monitoring, adaptive process control, and predictive maintenance contribute to a paradigm shift in pasta manufacturing. A comparative analysis with traditional methods underscores the efficiency gains and quality improvements achieved through these innovations.

Production Line Performance

Assessing the overall performance of the Spaghetti Pasta Production Line reveals a remarkable increase in output capacity. The fully automated system not only expedites the production process but also ensures a higher volume of consistently high-quality pasta. Real-world examples of successful implementation in renowned brands like Barilla, De Cecco, Creamette, San Giorgio, and Great Value showcase the tangible benefits in terms of increased productivity and market competitiveness.

Case Studies

This section delves into case studies of companies and facilities that have embraced the Spaghetti Pasta Production Line. Examining the impact on production efficiency and energy consumption, these cases serve as practical examples of how this technology has revolutionized pasta manufacturing. Insights from industry leaders and experts further validate the transformative effects witnessed in these real-world scenarios.

Future Trends

Looking ahead, this section explores potential future developments and advancements in pasta production technology. Predictions for the evolution of Spaghetti Pasta Production Line technologies encompass areas such as enhanced automation, integration with Industry 4.0 principles, and further strides in sustainability. Experts in the field provide insights into the trajectory of pasta manufacturing.

FAQs: Common Questions about Spaghetti Pasta Production Line

1. Q: How does the fully automatic operation of the Spaghetti Pasta Production Line benefit manufacturers?

A: The fully automatic operation eliminates the need for manual labor at various stages of pasta production. This not only enhances efficiency but also ensures consistency in product quality. Manufacturers experience increased production capacity and reduced operational costs.

2. Q: Are there any notable energy-efficient components in the Spaghetti Pasta Production Line?

A: Absolutely. The production line incorporates energy recovery systems and smart power management, optimizing energy usage. This not only aligns with sustainability goals but also proves to be economically advantageous for pasta manufacturers in the long run.

3. Q: How do technological innovations in the Spaghetti Pasta Production Line contribute to quality improvement?

A: Technological innovations such as real-time quality monitoring and adaptive process control ensure that the pasta production process is continually optimized. This results in a higher quality of pasta with fewer variations, meeting stringent industry standards.

4. Q: Can the Spaghetti Pasta Production Line be integrated with existing manufacturing setups?

A: Yes, the adaptability of the Spaghetti Pasta Production Line allows for integration with existing manufacturing setups. This flexibility ensures that pasta manufacturers can upgrade their processes without undergoing a complete overhaul.

5. Q: What real-world impact has the Spaghetti Pasta Production Line had on renowned pasta brands like Barilla, De Cecco, and others?

A: Renowned brands adopting the Spaghetti Pasta Production Line have witnessed significant improvements in production efficiency and product quality. The enhanced capabilities of the production line contribute to the reputation and competitiveness of these brands in the market.

6. Q: How does the Spaghetti Pasta Production Line address environmental concerns in pasta manufacturing?

A: The energy-efficient design of the production line minimizes its environmental footprint. By reducing energy consumption and incorporating sustainable practices, the Spaghetti Pasta Production Line aligns with global efforts toward environmentally friendly food production.

Conclusion

In conclusion, the Spaghetti Pasta Production Line emerges as a game-changer in the realm of pasta manufacturing. Its fully automatic operation, energy-efficient design, and technological innovations not only meet the current demands of the industry but also pave the way for a sustainable and competitive future. As pasta manufacturers navigate the evolving landscape, embracing such advancements becomes crucial for staying ahead in a dynamic market. The Spaghetti Pasta Production Line, with its unprecedented features, exemplifies the fusion of technology and tradition in crafting the perfect pasta.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

DRY PASTA PRESS MACHINE

DRY PASTA PRESS MACHINE Combined Automatic Pasta Sheeter

Combined Automatic Pasta Sheeter Spaghetti Pasta Production Line

Spaghetti Pasta Production Line PRECOOKED PASTA PRODUCTION LINE

PRECOOKED PASTA PRODUCTION LINE