- Shandong Loyal Industrial Co.,Ltd.

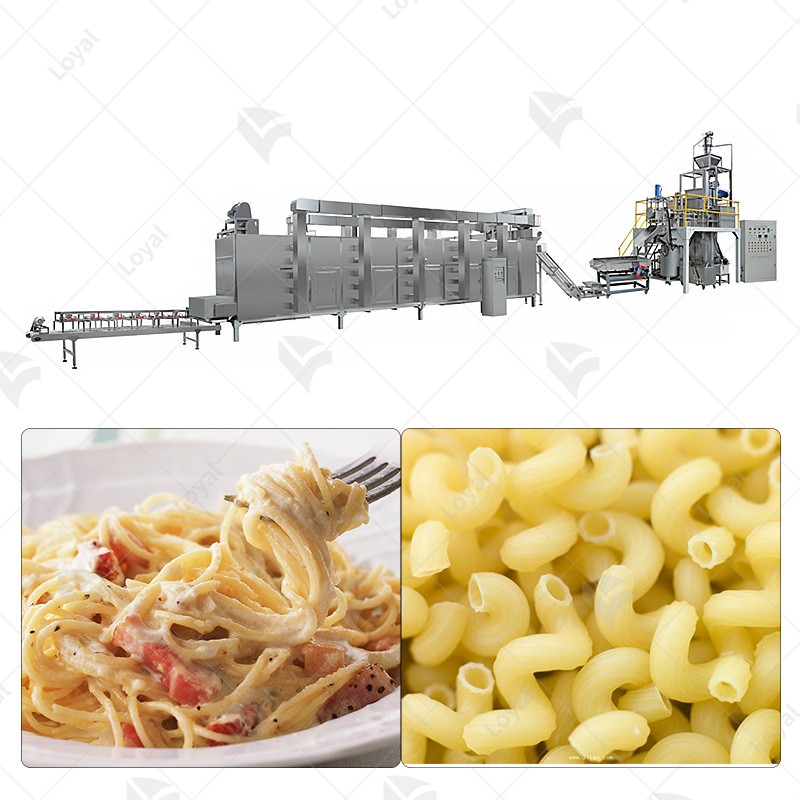

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> What You Must Know About Mastering Pasta Machines for Sustainable Pasta Production

What You Must Know About Mastering Pasta Machines for Sustainable Pasta Production

What You Must Know About Mastering Pasta Machines for Sustainable Pasta Production

Introduction

Pasta machines have become integral in modern kitchens, transforming the way both home and commercial cooks approach pasta production. Their significance lies not just in convenience but also in meeting the increasing demand for efficient and sustainable pasta-making methods.

Traditional pasta-making processes present challenges in terms of time and effort. This section explores the necessity for a shift towards automation, emphasizing the advantages it brings to streamline the pasta production process while ensuring sustainability.The Macaroni Pasta Maker Machines technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from GEA(PAVAN) and Unifood Machinery .

This part sets the stage for the article, highlighting the central theme of fully Macaroni Pasta Maker Machines. The emphasis is on how these machines play a pivotal role in achieving both effortless operation and sustainability, aligning with the demands of modern food production.

Technology Behind Effortless Pasta Production

1. Components of Fully Macaroni Pasta Maker Machines

- Pasta Extrusion Systems: Explore the advanced pasta extrusion systems that form the core of fully Macaroni Pasta Maker Machines. Discuss how these systems ensure precise shaping of various pasta types.

- Integrated Mixing and Kneading: Highlight the incorporation of mixing and kneading components, emphasizing their role in achieving the perfect pasta dough consistency.

- Smart Sensors and Control Systems: Discuss the use of smart sensors and control systems that monitor and adjust variables like temperature and humidity in real-time for optimal pasta production.

2.Smart Automation and Precision

- Artificial Intelligence in Pasta Making: Explore how artificial intelligence contributes to precision by learning and adapting to different pasta recipes. Emphasize the role of AI in minimizing errors and maximizing efficiency.

- Automated Ingredient Dispensing: Discuss automated ingredient dispensing systems, ensuring accurate proportions and reducing the margin of error in the pasta-making process.

- Quality Control Mechanisms: Highlight the incorporation of quality control mechanisms, including optical sensors and imaging technology, ensuring each pasta meets quality standards.

3. Sustainability Features in Modern Pasta Machines

- Energy-Efficient Motors: Discuss the use of energy-efficient motors in pasta machines, contributing to overall sustainability by reducing energy consumption.

- Recyclable Materials: Explore how manufacturers are incorporating recyclable and eco-friendly materials in the construction of pasta machines, aligning with sustainability goals.

- Water Conservation Technologies: Highlight technologies aimed at water conservation during the pasta production process, emphasizing the importance of reducing water usage.

Effortless Operation and User Experience

1. Simplifying Pasta Production for Home Cooks

- Intuitive Interfaces: Discuss the design of intuitive interfaces on pasta machines for home use, ensuring that even novice users can operate the machine effortlessly.

- One-Touch Operation: Highlight the convenience of one-touch operation, allowing users to produce high-quality pasta with minimal effort.

- Recipe Presets: Explore how pasta machines for home cooks often come with pre-programmed recipe presets, simplifying the process of making various pasta types.

2. Commercial Applications: Streamlining Pasta Production in Restaurants

- High-Volume Processing: Discuss how fully automatic pasta machines in commercial settings are designed for high-volume processing, meeting the demands of busy restaurants.

- Customization Options: Explore customization features that cater to the specific needs of restaurants, allowing chefs to create signature pasta dishes effortlessly.

- Remote Monitoring: Highlight the integration of remote monitoring capabilities, enabling chefs to oversee pasta production even when away from the machine.

3. Enhancing Culinary Creativity with Pasta Machines

- Attachment Compatibility: Discuss the compatibility of pasta machines with various attachments, enabling chefs to experiment with different pasta shapes and styles.

- Variable Speed Control: Highlight the inclusion of variable speed control, providing chefs with the flexibility to adjust the pasta-making process based on specific culinary preferences.

- User-Friendly Maintenance: Emphasize how user-friendly maintenance features enhance the overall user experience, ensuring chefs can focus on creativity rather than complex upkeep.

Sustainability in Pasta Production

Addressing the broader spectrum of sustainability, this section explores how pasta machines contribute to eco-friendly pasta production. From ingredient choices to packaging, the focus is on sustainable practices throughout the production cycle.

Highlighting another aspect of sustainability, this part delves into how automation reduces waste and optimizes resources in pasta production. It sheds light on the environmental benefits associated with minimizing the ecological footprint.

Ensuring authenticity and credibility, this section explores industry certifications and standards for sustainable pasta machine manufacturing. The discussion underscores the importance of choosing machines aligned with stringent environmental regulations.

Future Trends and Innovations

Looking into the future, this section discusses upcoming technologies shaping the design of pasta machines. It explores innovations that promise to enhance efficiency, sustainability, and the overall user experience.Examining the intersection of culinary trends and machine development, this part explores how shifts in consumer preferences influence the ongoing development of pasta machines. The adaptability of machines to changing culinary trends is a central theme.

Conclusion

Summarizing the key takeaways, this section recaps the mastery achieved through fully automated and sustainable pasta production. It reinforces the benefits of embracing automation for effortless and high-quality pasta making.In the concluding remarks, the focus is on embracing the future of pasta machine technology. The section encourages readers to be at the forefront of advancements in sustainable and effortless pasta production.

FAQs: Common Questions About Pasta Machines

1. What distinguishes fully automatic pasta machines from manual ones?

Fully automatic pasta machines incorporate advanced technology to streamline the pasta-making process. Unlike manual machines, they require minimal intervention, providing convenience and efficiency.

2. Are these machines suitable for home use, or are they more geared towards commercial kitchens?

Modern fully automatic pasta machines cater to both home cooks and commercial kitchens. They come in various sizes and capacities, making them adaptable to different culinary settings.

3. How do these machines contribute to sustainability in pasta production?

Fully automatic pasta machines contribute to sustainability by integrating eco-friendly practices. They often feature energy-efficient components, utilize sustainable materials, and support waste reduction throughout the production cycle.

4. Can pasta machines accommodate different types of pasta?

Yes, one of the advantages of fully automatic pasta machines is their versatility. They can accommodate various pasta shapes and types, allowing for creativity and diversity in pasta production.

5. What certifications or standards should consumers look for in sustainable pasta machines?

Consumers seeking sustainable pasta machines should look for certifications such as ISO 14001 for environmental management and certifications from relevant authorities ensuring adherence to sustainable manufacturing practices.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Dry Pasta Production Line

Dry Pasta Production Line Macaroni Pasta Production Line

Macaroni Pasta Production Line Spaghetti Pasta Production Line

Spaghetti Pasta Production Line Combined Automatic Pasta Sheeter

Combined Automatic Pasta Sheeter