- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Achieving Optimal Performance: The Ultimate Fully Automated Spaghetti Production Line for Energy Efficiency

Achieving Optimal Performance: The Ultimate Fully Automated Spaghetti Production Line for Energy Efficiency

Achieving Optimal Performance: The Ultimate Fully Automated Spaghetti Production Line for Energy Efficiency

Introduction

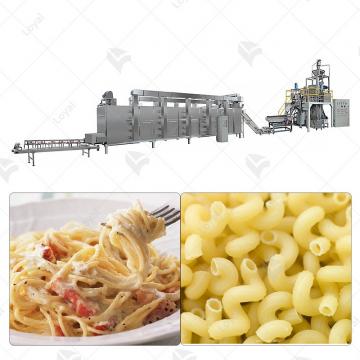

In the realm of food manufacturing, the integration of automation has revolutionized processes, and nowhere is this more evident than in spaghetti production. This article explores the transformative journey of the spaghetti production line, particularly focusing on achieving optimal performance through full automation and energy efficiency.The Macaroni Pasta Production Line technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from Lineapasta and lazzaretti.

The significance of automation in spaghetti production cannot be overstated. As consumer demands for high-quality pasta continue to rise, manufacturers seek ways to enhance efficiency and meet these demands. Fully automated systems have emerged as a solution to streamline the production process, ensuring precision and consistency.

Challenges addressed by fully automated systems include the need for increased production speed, maintaining product quality, and optimizing resource utilization. This article delves into how the ultimate fully automated spaghetti production line tackles these challenges head-on, marking a paradigm shift in the food manufacturing industry.

The importance of energy efficiency in modern production lines is a driving force behind innovation. As the world becomes increasingly focused on sustainable practices, manufacturers are compelled to adopt energy-efficient solutions. This introduction sets the stage for an in-depth exploration of the ultimate fully automated spaghetti production line and its role in achieving optimal performance while prioritizing energy efficiency.

The Ultimate Fully Automated Spaghetti Production Line

Exploring the cutting-edge technologies incorporated into the ultimate fully automated spaghetti production line reveals a marriage of robotics and artificial intelligence. Robotics brings precision and speed to the manufacturing process, while artificial intelligence ensures seamless operations. These advanced features not only enhance the overall efficiency but also contribute to the reliability and quality of the end product.

The detailed explanation in this section outlines how automation optimizes the spaghetti manufacturing process. The integration of robotics and AI leads to increased production speed and unparalleled accuracy. With repetitive tasks handled by machines, human resources can be redirected to more intricate aspects, further improving overall efficiency. This section emphasizes how the ultimate fully automated spaghetti production line sets new benchmarks in the industry.

Energy Efficiency in Spaghetti Production

The discussion on sustainable practices adopted in the production line sheds light on the environmental consciousness of modern manufacturing. The ultimate fully automated spaghetti production line prioritizes sustainable practices, aligning with global efforts to reduce the carbon footprint. This section explores how energy-efficient operations contribute to a more sustainable and environmentally friendly production process.

Utilizing energy-efficient equipment becomes a focal point in resource conservation. The section delves into the specific equipment and technologies employed to minimize resource consumption. Case studies are presented, showcasing real-world examples of reduced energy consumption and waste generation, providing tangible evidence of the positive impact on resource conservation.

This section examines real-world applications and success stories of companies that have embraced the ultimate fully automated spaghetti production line. By showcasing these cases, readers gain insights into the practical benefits and positive outcomes experienced by manufacturers who made the transition to full automation.

Future Trends and Innovations

Predicting the future of automated spaghetti production involves exploring emerging technologies and innovations. This section looks ahead, discussing the potential advancements that may further revolutionize the industry. From machine learning to enhanced connectivity, the ultimate fully automated spaghetti production line is poised to evolve in tandem with technological progress.

Conclusion

In conclusion, the ultimate fully automated spaghetti production line stands as a beacon of innovation in food manufacturing. The benefits, ranging from heightened efficiency to energy conservation, position this technology as a cornerstone for the future. As we reflect on the journey from challenges to achievements, it becomes clear that the role of energy efficiency is pivotal in shaping the future landscape of food manufacturing.

This comprehensive exploration of the ultimate fully automated spaghetti production line showcases its transformative impact on efficiency and sustainability. From advanced technological features to real-world success stories, the article navigates through the intricacies of this innovation. The journey concludes with a resounding affirmation of the role energy efficiency plays in steering the future trajectory of food manufacturing.

FAQs: Frequently Asked Questions about Spaghetti Production Line

1 。What are the key features of a fully automated spaghetti production line?

The key features include advanced robotics and artificial intelligence, enabling precision, speed, and seamless operations. These features contribute to enhanced efficiency and consistent product quality.

2. How does automation optimize the spaghetti manufacturing process?

Automation optimizes the process by handling repetitive tasks, allowing human resources to focus on more intricate aspects. This leads to increased production speed and accuracy.

3. How does the ultimate fully automated spaghetti production line contribute to energy efficiency?

The production line adopts sustainable practices and energy-efficient equipment, minimizing environmental impact. Real-world case studies highlight reduced energy consumption and waste generation, showcasing its positive impact on resource conservation.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Short-Cut Pasta Production Line

Short-Cut Pasta Production Line Combined Pasta Production Line

Combined Pasta Production Line Macaroni Pasta Production Line

Macaroni Pasta Production Line Combined Pasta Machine

Combined Pasta Machine