- Shandong Loyal Industrial Co.,Ltd.

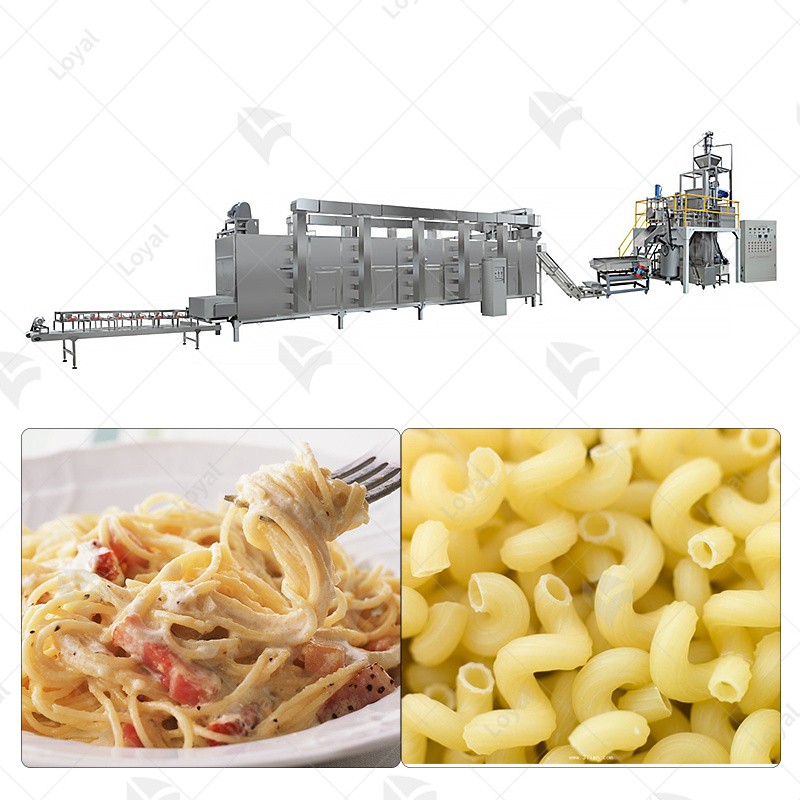

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Cutting-Edge Technology: Full Automation in Industrial Pasta Making for High Efficiency and Energy Conservation

Cutting-Edge Technology: Full Automation in Industrial Pasta Making for High Efficiency and Energy Conservation

Cutting-Edge Technology: Full Automation in Industrial Pasta Making for High Efficiency and Energy Conservation

Introduction

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from BUHLER and FEN in the production of its macaroni.In the dynamic landscape of Dry Pasta Production Line, the infusion of cutting-edge technology has ushered in a new era of efficiency and sustainability. This article explores the transformative impact of full automation on the pasta manufacturing sector, emphasizing its role in achieving both high efficiency and energy conservation.

Significance of Cutting-Edge Technology

The significance of cutting-edge technology lies in its ability to revolutionize traditional methods of pasta production. Full automation emerges as a crucial component in enhancing efficiency and addressing the pressing need for sustainable practices in the industry.

Evolution of Industrial Pasta Making Technology

Understanding the journey of technology in industrial pasta making is vital to appreciating its current cutting-edge status. This section will trace the evolution from manual and semi-automated processes to the sophisticated technologies employed today.

Milestones in Automation

Highlighting milestones in the automation of pasta making processes provides a historical context for the advancements leading to full automation. A timeline approach will showcase the industry's technological journey, underlining key breakthroughs that paved the way.

Full Automation: A Catalyst for High Efficiency

Full automation emerges as a transformative catalyst for achieving high efficiency in industrial pasta making. This section will delve into how automated systems streamline processes, significantly reduce production time, and enhance overall efficiency.

Precision and Speed

Emphasizing the precision and speed achieved through full automation underscores its direct impact on the efficiency of industrial pasta making. Technologies such as robotics and artificial intelligence take center stage, contributing to the industry's cutting-edge advancements.

Energy Conservation in Automated Pasta Manufacturing

Examining the role of full automation in energy conservation within industrial pasta making becomes the focal point of this section. Eco-friendly aspects of automated systems, coupled with sustainable practices, shape a manufacturing process aligned with environmental considerations.

Sustainable Practices

Highlighting specific sustainable practices integrated into automated pasta manufacturing showcases the industry's commitment to environmental responsibility. This includes the adoption of energy-efficient machinery and innovative waste reduction strategies.

Case Studies: Successful Implementation of Cutting-Edge Technology

Real-world case studies featuring industry leaders like Banza, Colavita, Garofalo, and Whole Foods 365 Everyday Value provide tangible examples of successful implementation of cutting-edge technology and full automation.

Comparative Analysis

Conducting a comparative analysis of these case studies sheds light on the varied approaches and technologies adopted by different manufacturers. This highlights the versatility and effectiveness of cutting-edge technology in achieving high efficiency and energy conservation.

Overcoming Challenges in Full Automation

Addressing potential challenges associated with implementing full automation is crucial for a comprehensive understanding. This section will explore strategies and solutions employed by companies to overcome obstacles, ensuring a smooth transition to automated systems.

Technological Adaptation

Highlighting the importance of continuous technological adaptation underscores the dynamic nature of industrial pasta making. Industry-wide efforts to stay ahead of challenges showcase the resilience and commitment to innovation.

Future Trends: Advancements in Industrial Pasta Making Technology

Exploring future trends in industrial pasta making technology provides insights into upcoming innovations. This section will discuss emerging technologies like advanced robotics, machine learning, and sustainable innovations, shaping the industry's future.

Integration of Emerging Technologies

Discussing how emerging technologies are being integrated will provide a forward-looking perspective, offering glimpses into the industry's evolving landscape.

Conclusion

In conclusion, this article has traversed the realms of cutting-edge technology and full automation in industrial pasta making. It underscores their paramount significance in achieving high efficiency and energy conservation. As the industry embraces these advancements, the commitment to staying at the forefront of technological progress remains unwavering.

Common Questions about Industrial Pasta Making

1 What brands are leading the way in implementing cutting-edge technology in pasta making?

Banza, Colavita, Garofalo, and Whole Foods 365 Everyday Value are prominent examples of brands at the forefront of implementing cutting-edge technology in industrial pasta making. These brands serve as industry benchmarks for innovation and efficiency.

2 How does full automation contribute to the efficiency of industrial pasta making?

Full automation streamlines pasta manufacturing processes by minimizing human intervention, reducing production time, and ensuring precision. This results in increased efficiency, allowing manufacturers to meet growing demands with consistency and speed.

3 Are sustainable practices integrated into automated pasta manufacturing?

Yes, sustainable practices play a crucial role in automated pasta manufacturing. Brands like Colavita and Whole Foods 365 Everyday Value are incorporating energy-efficient machinery and innovative waste reduction strategies, aligning with environmental considerations.

4 Can smaller pasta manufacturers benefit from full automation?

Smaller pasta manufacturers can indeed benefit from full automation by adopting scalable solutions and phased implementation. The case studies highlighted in the article demonstrate that advancements in technology are accessible and adaptable to companies of varying sizes.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Vacuum Extruder Pasta Machine

Vacuum Extruder Pasta Machine Combined Automatic Pasta Sheeter

Combined Automatic Pasta Sheeter Spaghetti Pasta Production Line

Spaghetti Pasta Production Line Short-Cut Pasta Production Line

Short-Cut Pasta Production Line