- Shandong Loyal Industrial Co.,Ltd.

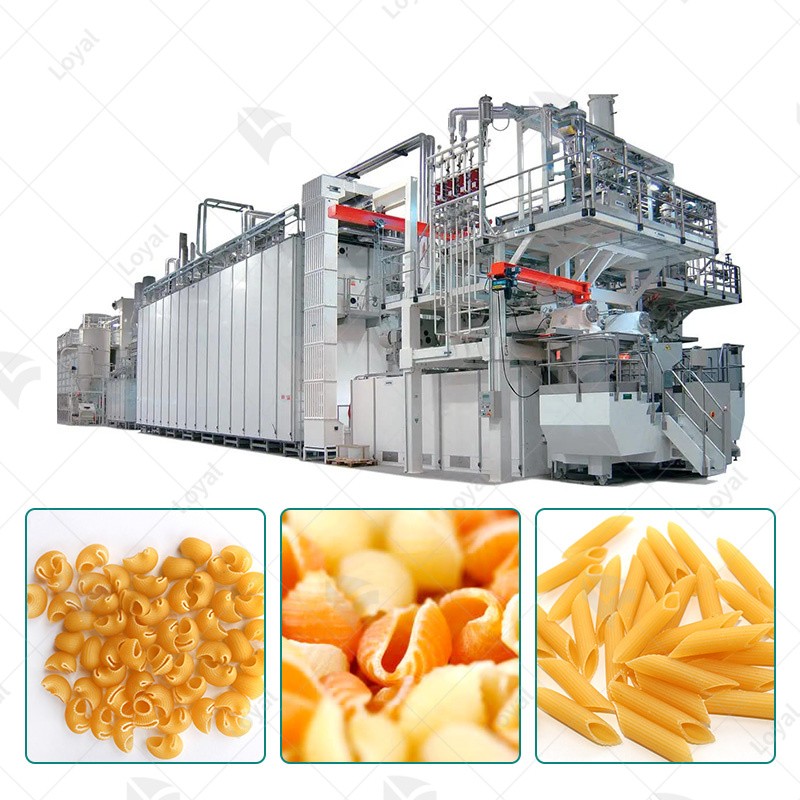

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Elevate Productivity with a Fully Automatic Pasta Macaroni Machine: Efficiency Redefined

Elevate Productivity with a Fully Automatic Pasta Macaroni Machine: Efficiency Redefined

Elevate Productivity with a Fully Automatic Pasta Macaroni Machine: Efficiency Redefined

Introduction

The introduction sets the stage by providing an overview of the modern pasta and macaroni production industry. It emphasizes the significance of automation in enhancing productivity within this dynamic sector. The focus is on introducing the transformative impact that fully automatic pasta macaroni machines have on redefining efficiency in the production process.The Macaroni Pasta Maker Machines technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from HEMAKS and Capitanio.

Evolution of Pasta Macaroni Production Technology

This section delves into the historical background of pasta and macaroni production methods, highlighting the challenges faced in traditional manufacturing and the compelling need for innovation. It explores the industry's transition from manual to automated processes, laying the foundation for the emergence of advanced pasta macaroni machines.

Types of Fully Automatic Pasta Macaroni Machines

The comprehensive exploration of various fully automatic pasta macaroni machines takes center stage in this section. It aims to differentiate factors and discuss specific functionalities of each machine type, providing valuable insights for businesses seeking the most suitable equipment for their unique production needs.

Key Features and Technologies

Meticulously examining the key features that contribute to the efficiency of fully automatic pasta macaroni machines, this section sheds light on the integration of cutting-edge technologies. This includes artificial intelligence, machine learning, smart sensors, and real-time data analytics, showcasing how these features impact production optimization.

Fully automatic pasta macaroni machines leverage advanced artificial intelligence (AI) algorithms to enhance decision-making processes. These intelligent systems analyze data in real-time, enabling adaptive responses to varying production conditions. AI optimizes the entire manufacturing workflow, from ingredient mixing to shaping, ensuring consistent product quality.

Machine learning algorithms play a pivotal role in fine-tuning the performance of pasta macaroni machines. These systems learn from historical data, adapting and optimizing parameters such as mixing duration, extrusion speed, and drying time. The result is a more precise and efficient production process, reducing wastage and improving overall output quality.

State-of-the-art pasta macaroni machines integrate smart sensors that monitor critical parameters throughout the production cycle. These sensors provide real-time feedback on factors like temperature, humidity, and pressure, allowing operators to make instant adjustments for optimal conditions. The continuous monitoring ensures a consistent and controlled production environment.

Efficiency Standards in Pasta Production

An in-depth analysis unfolds in this section, demonstrating how fully automatic pasta macaroni machines redefine efficiency in the production process. It includes a comparative study with traditional and semi-automated methods, highlighting streamlined processes and minimized errors achieved through innovative technologies.

Fully automatic pasta macaroni machines revolutionize efficiency by automating traditionally manual-intensive processes. From dough preparation to shaping and packaging, automation minimizes human intervention, reducing the risk of errors and ensuring a continuous and seamless production flow. This streamlined approach significantly enhances overall efficiency standards.

A comparative study delves into the differences between fully automatic machines and traditional pasta production methods. It highlights the efficiency gains achieved through automation, such as increased production speed, precise ingredient measurements, and standardized product quality. This section emphasizes the substantial advancements offered by fully automatic machines over conventional practices.

Innovative technologies integrated into fully automatic pasta macaroni machines contribute to error reduction. Precision-controlled processes, aided by AI and machine learning, minimize variations in product dimensions and consistency. This not only improves efficiency but also ensures a higher-quality end product, meeting stringent industry standards.

Efficiency in pasta production is redefined as fully automatic machines consistently deliver products with enhanced quality. The controlled and monitored production environment, coupled with advanced technologies, results in pasta and macaroni products that meet or exceed industry standards. The reduction in errors contributes to a higher level of output consistency.

Real-world examples take the spotlight in this section, showcasing successful implementations of fully automatic pasta macaroni machines. It emphasizes brands and manufacturers that have achieved increased efficiency and set new standards. Additionally, case studies illustrate the positive impact of these machines on production output.

Maintenance and Optimization

This section provides guidance on maintenance practices essential for ensuring continuous high efficiency in fully automatic pasta macaroni machines. Strategies for optimizing performance are discussed, emphasizing the role of training and support in maximizing the benefits of automated production.

A forward-looking perspective is adopted in this section, examining upcoming trends and developments in the pasta production industry. Predictions for the future of fully automatic pasta macaroni machine technology are presented, along with anticipated advancements that will further enhance efficiency and production capabilities.

Challenges and Solutions

The discussion in this section revolves around challenges faced in adopting fully automatic pasta macaroni machines. Proposed solutions and strategies are provided for overcoming these challenges, addressing the dynamic landscape and adapting to industry demands.

Conclusion

The conclusion serves as a recap of how fully automatic pasta macaroni machines elevate productivity and redefine efficiency. It concludes with final thoughts on the continuous innovation shaping the future of pasta manufacturing, emphasizing the industry's commitment to setting and exceeding efficiency benchmarks.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Combined Pasta Production Line

Combined Pasta Production Line Combined Pasta Machine

Combined Pasta Machine Vacuum Extruder Pasta Machine

Vacuum Extruder Pasta Machine Instant Pasta Production Line

Instant Pasta Production Line