- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Embracing Automation: High Efficiency and Energy Savings with Fully Automated Macaroni Production Machine

Embracing Automation: High Efficiency and Energy Savings with Fully Automated Macaroni Production Machine

Embracing Automation: High Efficiency and Energy Savings with Fully Automated Macaroni Production Machine

Introduction

In the ever-evolving landscape of the modern macaroni production industry, the significance of automation in manufacturing processes cannot be overstated. This article delves into the transformative impact of fully automated macaroni production machines, focusing on achieving high efficiency and energy savings.The Macaroni Pasta Maker Machines technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from Capitanio and Gidamak.

As we witness a paradigm shift from traditional methods to advanced technologies, the concept of fully automated macaroni production machines emerges as a beacon of innovation. This introduction sets the stage for an exploration of how automation revolutionizes the macaroni production process.

Evolution of Macaroni Production Technology

To understand the importance of fully automated machines, a journey through the historical background of macaroni production becomes essential. Traditional manufacturing methods faced challenges, paving the way for innovation and the transition from manual to automated processes. This section establishes the historical context and the need for a technological evolution in macaroni production.

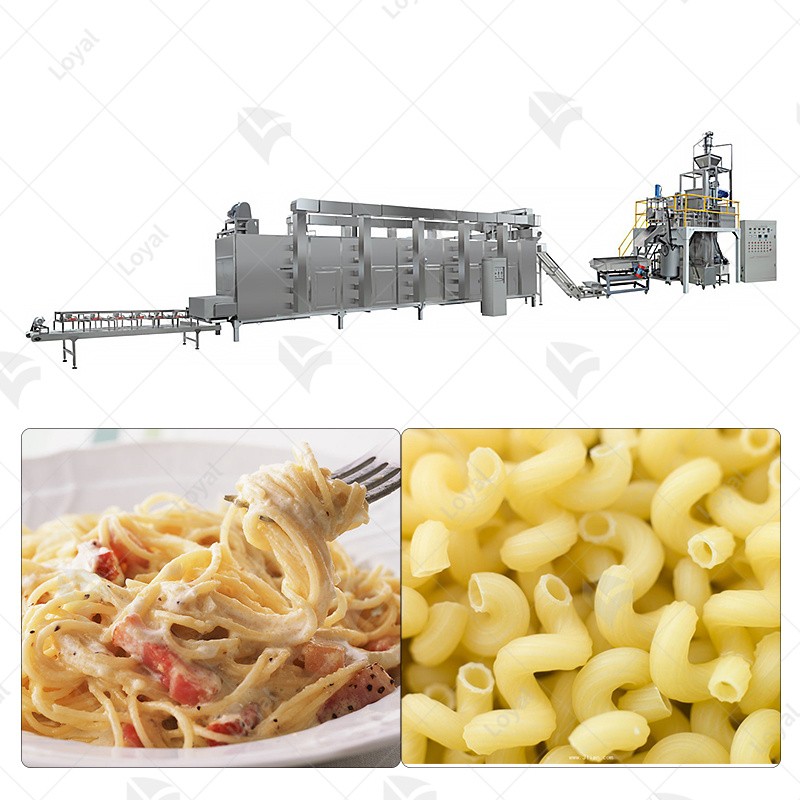

Fully Automated Macaroni Production Machines

This segment delves into a comprehensive exploration of fully automated macaroni production machines. Highlighting key features and advanced technologies, the focus is on how these machines not only streamline production but also emphasize efficiency and energy-saving capabilities. It lays the foundation for a detailed examination of the components that contribute to these advancements.

Components of Fully Automated Machines

Breaking down the intricate components within fully automated macaroni production machines, this section provides insights into their inner workings. Each component's role in the manufacturing process is explained, emphasizing their contribution to achieving high efficiency and energy savings. This knowledge forms the basis for understanding the revolutionary impact of automation.

Efficiency and Energy Savings Through Automation

An in-depth analysis follows, showcasing how fully automated machines reshape efficiency in macaroni production. Through a comparative study with traditional and semi-automated methods, the article highlights not only streamlined processes but also significant energy-saving features. Real-world examples and case studies contribute to illustrating the tangible benefits of embracing automation.

Technological Advancements in Macaroni Production

This section explores recent technological innovations, bringing artificial intelligence and machine learning into the spotlight. By integrating these technologies, fully automated macaroni production machines set new standards for efficiency. The role of smart sensors and real-time data analytics in achieving energy-efficient operations is thoroughly examined.

Case Studies

Real-world success stories take center stage, featuring prominent brands such as DeLallo, Faella, Pastificio Di Martino, and Rao's Homemade. These case studies provide tangible evidence of how these brands have achieved high efficiency, energy savings, and sustainability through the adoption of fully automated macaroni production machines.

Future Trends in Macaroni Manufacturing

Anticipating the future, this section explores upcoming trends and developments in the macaroni production industry. Predictions for the continuous evolution of fully automated technology set the stage for advancements that will further enhance efficiency and energy savings in macaroni manufacturing.

Challenges and Solutions

Navigating the path of innovation, challenges in adopting fully automated macaroni production are addressed. Proposed solutions and strategies pave the way forward, emphasizing the industry's commitment to sustainability and eco-friendly practices. This section encourages a holistic view of the challenges and opportunities in embracing automation.

Conclusion

In conclusion, the article recaps the multifaceted benefits of embracing automation in macaroni production. It emphasizes how continuous innovation shapes the future of efficient and sustainable manufacturing. The dual impact of achieving high efficiency and energy savings through fully automated macaroni production machines underscores the transformative journey the industry is on.

Common Questions about Fully Automated Macaroni Production Machines

1. What defines a fully automated macaroni production machine?

A: A fully automated macaroni production machine is an advanced manufacturing system designed to handle various stages of macaroni production with minimal human intervention. It incorporates cutting-edge technologies for mixing, shaping, drying, cutting, and packaging, ensuring a highly efficient and streamlined process.

2. How do fully automated machines differ from traditional methods?

A: Fully automated machines differ significantly from traditional methods by minimizing reliance on manual labor. These machines operate seamlessly with advanced features such as smart sensors, artificial intelligence, and real-time analytics, contributing to increased efficiency, reduced errors, and sustainable practices.

3. What are the key features of fully automated macaroni production machines?

A: Key features include automated mixing and kneading, precise shaping, advanced drying methods, intelligent cutting mechanisms, and automated packaging systems. These features ensure consistent product quality, optimal production efficiency, and reduced environmental impact through energy-saving capabilities.http://www.pasta-productionline.com/uploaded_images/20964.jpg

4. Which brands have successfully implemented fully automated machines?

A: Renowned brands such as DeLallo, Faella, Pastificio Di Martino, and Rao's Homemade have embraced fully automated macaroni production machines with notable success. These brands serve as industry leaders, showcasing the transformative impact of automation on efficiency and sustainability.

5. How do fully automated machines contribute to efficiency enhancement?

A: Fully automated machines enhance efficiency by streamlining the entire production process. The integration of advanced technologies reduces production time, minimizes errors, and ensures a consistent output. This contributes to meeting the demands of the modern macaroni market with precision and reliability.

6. Are there challenges associated with adopting fully automated macaroni production?

A: While the benefits are substantial, challenges may include initial implementation costs, the need for specialized training, and potential resistance to change. However, the long-term advantages in terms of increased productivity and enhanced product quality often outweigh these initial challenges.

7. What does the future hold for fully automated macaroni production technology?

A: Future trends suggest continuous innovation in fully automated macaroni production technology. Anticipated advancements include further integration of artificial intelligence, enhanced energy-efficient systems, and a broader range of customization options to cater to evolving consumer preferences.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Instant Pasta Production Line

Instant Pasta Production Line Long-Cut Pasta Production Line

Long-Cut Pasta Production Line Macaroni Pasta Production Line

Macaroni Pasta Production Line PRECOOKED PASTA PRODUCTION LINE

PRECOOKED PASTA PRODUCTION LINE