- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Embracing Innovation: Full Automation in Macaroni Production Line for High Efficiency

Embracing Innovation: Full Automation in Macaroni Production Line for High Efficiency

Embracing Innovation: Full Automation in Macaroni Production Line for High Efficiency

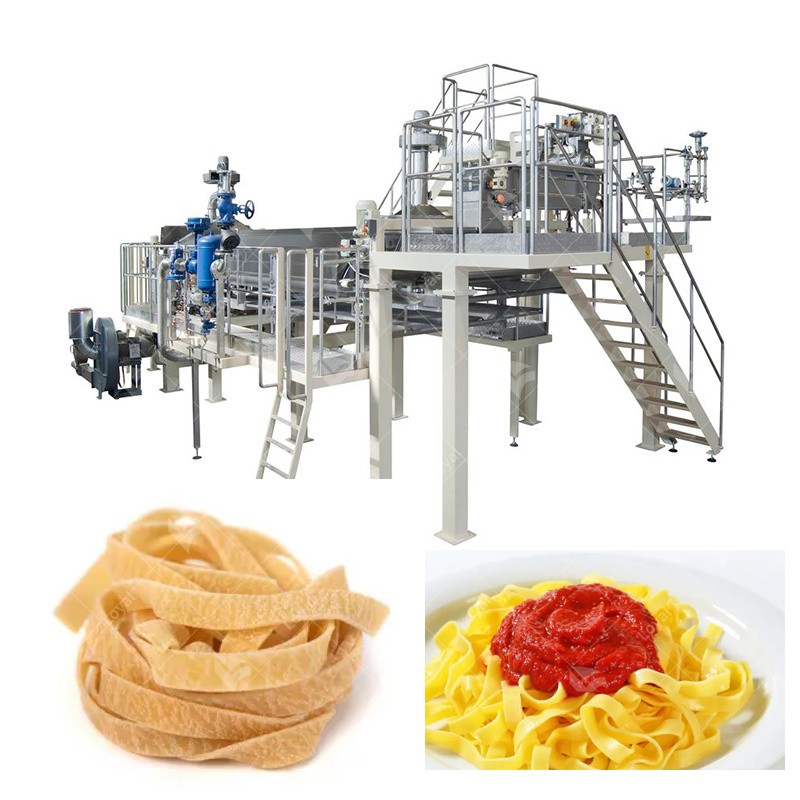

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from SARP and FEN in the production of its macaroni.The landscape of macaroni production is undergoing a profound transformation marked by the introduction of the Macaroni Pasta Production Line. This article delves into the innovative realm of full automation within the Macaroni Production Line, emphasizing the critical role that efficiency and high-tech solutions play in shaping modern pasta manufacturing.

Embracing Full Automation in Macaroni Production Line

The Macaroni Production Line is characterized by a comprehensive embrace of full automation. This section explores the intricate components of the automated process, shedding light on how it revolutionizes macaroni crafting. The emphasis is on understanding how automation not only streamlines the manufacturing process but also enhances efficiency and energy-saving capabilities.

Technological Advancements in Macaroni Crafting

A closer look at the Macaroni Production Line reveals cutting-edge technology at its core. Advanced machinery is the driving force behind precision and consistency in macaroni manufacturing. This section details the role of innovation in shaping the future of pasta production, highlighting the significant technological strides within the Macaroni Production Line.

Efficiency and Energy Savings

One of the standout features of the Macaroni Production Line is the efficiency it brings to the pasta manufacturing process. This part of the article delves into the efficiency gains achieved through full automation. Additionally, it explores the integration of energy-saving features, showcasing how the Macaroni Production Line contributes to sustainable and eco-friendly pasta manufacturing.

Realizing High-Quality Macaroni Products

Full automation in the Macaroni Production Line ensures not just efficiency but also the production of high-quality macaroni. This section explores the impact of precision and consistency on the texture and taste of the final product. Real-world examples from leading macaroni brands, such as DeLallo, Faella, Pastificio Di Martino, Rao's Homemade, showcase the successful implementation of full automation in delivering exceptional pasta products.

Challenges and Future Developments

While full automation in macaroni production brings numerous benefits, this section acknowledges potential challenges in its adoption. The discussion extends to ongoing developments and innovations in the field, providing insights into how the Macaroni Production Line technology is expected to evolve in the future.

Consumer Perspective and Market Trends

Understanding how consumers perceive macaroni produced through automated processes is crucial. This section gathers insights into current market trends and preferences related to pasta products. It explores the influence of technological advancements on consumer choices, offering a comprehensive view of the consumer perspective in the evolving landscape of macaroni production.

Conclusion

In conclusion, the transformative impact of full automation in the Macaroni Production Line is profound. This article has explored the innovative technology, efficiency gains, and sustainable practices within the automated process. As we navigate the future of macaroni manufacturing, embracing automation becomes pivotal for an efficient, high-quality, and eco-friendly pasta industry.

FAQs: Frequently Asked Questions about Macaroni Production Line

Q1: How does full automation improve the efficiency of the Macaroni Production Line?

A1: Full automation optimizes the entire macaroni production process. By eliminating manual interventions and leveraging advanced technology, the Macaroni Production Line achieves unparalleled efficiency. Each stage, from ingredient mixing to final packaging, is seamlessly executed with precision, reducing production time and enhancing overall efficiency.

Q2: Are there specific energy-saving features integrated into the Macaroni Production Line?

A2: Absolutely. The Macaroni Production Line prioritizes sustainability through the incorporation of energy-saving features. This includes the use of efficient machinery, smart energy management systems, and innovations in the drying process. The result is not only high productivity but also a reduced environmental impact.

Q3: How does precision in the Macaroni Production Line impact the texture and taste of the final product?

A3: Precision is a cornerstone of the Macaroni Production Line. The advanced machinery ensures consistent sizing and shaping of macaroni, directly influencing the texture and taste of the final product. The uniformity achieved through precision enhances the overall dining experience, providing consumers with consistently high-quality macaroni.

Q4: Can you provide examples of leading macaroni brands adopting full automation?

A4: Certainly. Renowned brands such as DeLallo, Faella, Pastificio Di Martino, Rao's Homemade have embraced full automation in their Macaroni Production Lines. These industry leaders recognize the significance of advanced technology in ensuring the quality, efficiency, and consistency of their macaroni products.

Q5: What are the potential challenges in adopting full automation in macaroni production?

A5: While full automation brings numerous benefits, challenges may include initial investment costs, employee training, and the need for adaptation to new technologies. However, the long-term gains in efficiency, product quality, and sustainability often outweigh these initial hurdles.

In conclusion, the Frequently Asked Questions section sheds light on key aspects of the Macaroni Production Line. From the efficiency gains of full automation to the sustainability features integrated into the process, these FAQs provide valuable insights for those seeking to understand the innovative landscape of modern macaroni manufacturing. As consumers demand higher quality and sustainable practices, the Macaroni Production Line stands as a beacon of progress, ensuring a promising future for the pasta industry.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Long-Cut Pasta Production Line

Long-Cut Pasta Production Line Instant Pasta Production Line

Instant Pasta Production Line Macaroni Pasta Production Line

Macaroni Pasta Production Line Pasta Processing Equipment

Pasta Processing Equipment