- Shandong Loyal Industrial Co.,Ltd.

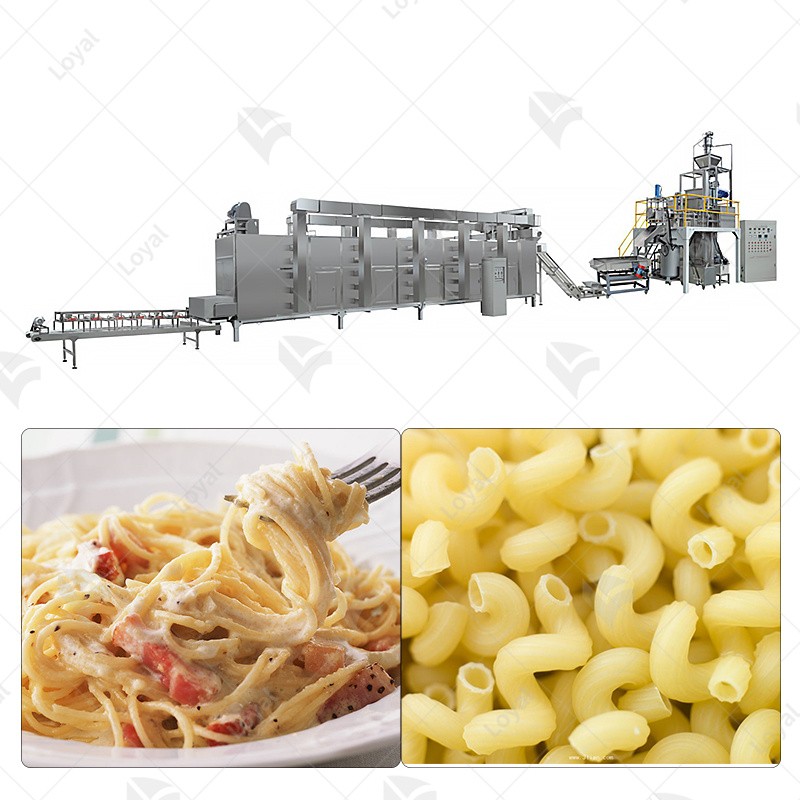

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Innovative Pasta Manufacturing Machines: A Leap in Efficiency and Energy Conservation

Innovative Pasta Manufacturing Machines: A Leap in Efficiency and Energy Conservation

Innovative Pasta Manufacturing Machines: A Leap in Efficiency and Energy Conservation

The evolution of pasta manufacturing has witnessed a paradigm shift with the advent of innovative pasta manufacturing machines. This article explores the transformative journey, focusing on efficiency and energy conservation in the realm of food industry machinery.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Tecalit and FEN in the production of its macaroni.

Evolution of Pasta Manufacturing Technology

The history of pasta production has evolved from traditional methods to the contemporary era of automation. With the rising demand for efficiency, pasta manufacturing machines have played a pivotal role in revolutionizing the industry. The integration of cutting-edge technology has paved the way for a more streamlined and effective pasta production process.

Key Features of Modern Pasta Manufacturing Machines

Modern pasta manufacturing machines boast advanced automation features that significantly enhance efficiency. These machines incorporate state-of-the-art technologies such as AI-driven processes, real-time monitoring, and adaptive control systems. The use of these technologies ensures precision in pasta production, leading to consistent quality and reduced wastage.

Additionally, energy-saving features have become a cornerstone of these machines. Utilizing sustainable energy sources, optimizing power consumption, and implementing eco-friendly manufacturing practices, these machines contribute to reducing the environmental footprint of pasta production. Manufacturers now have the capability to meet the growing demand for pasta while aligning with global sustainability goals.

Furthermore, customization capabilities have been enhanced, allowing manufacturers to cater to diverse consumer preferences. From different pasta shapes to variations in texture, these machines offer flexibility in production, enabling the creation of a wide array of pasta products.

In essence, modern pasta manufacturing machines represent a synergy of efficiency, sustainability, and versatility, setting new standards for the industry. As we delve deeper into the specifics of these machines, it becomes evident how they have become integral to the evolution of pasta production.

Case Studies

Several renowned brands in the pasta industry have successfully integrated innovative pasta manufacturing machines into their production processes. Anza, known for its commitment to quality, implemented these machines to enhance the precision and consistency of their pasta products. The result was a significant increase in production speed without compromising on the high standards that Anza is synonymous with.

Colavita, a brand recognized for its traditional Italian craftsmanship, embraced the efficiency of modern pasta manufacturing machines. The machines allowed Colavita to scale up production while maintaining the authentic taste and texture of their pasta. This successful implementation is a testament to the compatibility of innovation with traditional culinary values.

Garofalo, a brand with a rich heritage in pasta making, adopted cutting-edge machines to meet the growing demand for their products. The incorporation of energy-saving technologies not only optimized their production processes but also contributed to Garofalo's sustainability goals. This case study showcases how technology can align with a brand's commitment to both efficiency and environmental responsibility.

Whole Foods 365 Everyday Value, a key player in the organic and natural foods market, recognized the importance of sustainable practices in pasta manufacturing. By utilizing advanced pasta manufacturing machines, they were able to enhance their production efficiency while minimizing their ecological footprint. This case study demonstrates how a commitment to sustainability can go hand in hand with operational improvements.

Benefits and Impact on Sustainability

The benefits of adopting innovative pasta manufacturing machines extend beyond operational efficiency. One of the key advantages is the substantial reduction in energy consumption. By incorporating energy-saving technologies, manufacturers contribute to the overall sustainability of the food industry. This aligns with global efforts to reduce carbon footprints and promote environmentally conscious practices.

Furthermore, the precision and customization capabilities of these machines lead to a decrease in food wastage. Manufacturers can tailor production to meet specific market demands, minimizing excess inventory and ensuring that resources are utilized efficiently. This not only benefits the bottom line but also promotes a more sustainable and responsible approach to food production.

In terms of product quality, the use of advanced machines ensures consistency and uniformity in pasta production. Consumers can enjoy pasta products that meet high standards of taste and texture, contributing to overall satisfaction. This quality assurance is vital for brand reputation and customer loyalty, reinforcing the positive impact of innovative pasta manufacturing machines on the sustainability of the industry.

Challenges and Future Developments

While the benefits of innovative pasta manufacturing machines are substantial, challenges in their widespread adoption persist. Manufacturers may face initial capital investment concerns, as acquiring and implementing these advanced machines requires a significant upfront cost. Additionally, the need for specialized training to operate and maintain these high-tech systems poses a potential obstacle. However, as the industry continues to invest in research and development, addressing these challenges becomes a priority.

Looking ahead, future developments in pasta manufacturing machines are poised to address current challenges and push the boundaries of efficiency. The incorporation of artificial intelligence and machine learning holds the promise of even more streamlined operations, predicting and optimizing various aspects of pasta production. Collaboration between manufacturers and technology developers is likely to result in user-friendly interfaces and enhanced connectivity, allowing for real-time monitoring and control.

FAQs: Common Questions about Pasta Manufacturing Machines

Q1: How do innovative pasta manufacturing machines contribute to energy conservation?

A1: Innovative pasta manufacturing machines employ advanced energy-saving technologies such as efficient heating and cooling systems, as well as optimized production processes. This results in a significant reduction in overall energy consumption, aligning with sustainability goals.

Q2: Are there specific brands that have successfully implemented these machines?

A2: Yes, several renowned brands, including Anza, Colavita, Garofalo, and Whole Foods 365 Everyday Value, have embraced innovative pasta manufacturing machines. Their success stories serve as inspiration for the broader industry.

Q3: What challenges might manufacturers face in adopting these machines?

A3: Challenges include initial capital investment, the need for specialized training, and potential resistance to change. However, ongoing developments aim to address these challenges and facilitate a smoother transition.

Conclusion

In conclusion, the integration of innovative pasta manufacturing machines represents a monumental leap in the efficiency and sustainability of pasta production. The success stories of industry giants adopting these technologies underscore their transformative impact on speed, quality, and energy consumption. As challenges are tackled head-on, and future developments continue to unfold, the marriage of technology and pasta manufacturing promises a dynamic and prosperous future for this beloved culinary tradition. The journey towards more efficient and sustainable pasta production is well underway, with the industry poised for continued innovation and excellence.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

VACUUM PASTA EXTRUDER

VACUUM PASTA EXTRUDER Pasta Processing Equipment

Pasta Processing Equipment Dry Pasta Production Line

Dry Pasta Production Line Combined Pasta Production Line

Combined Pasta Production Line