- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Precision in Motion: Unveiling the 200kg Pasta Factory Machine with Vacuum Extrusion Technology

Precision in Motion: Unveiling the 200kg Pasta Factory Machine with Vacuum Extrusion Technology

Precision in Motion: Unveiling the 200kg Pasta Factory Machine with Vacuum Extrusion Technology

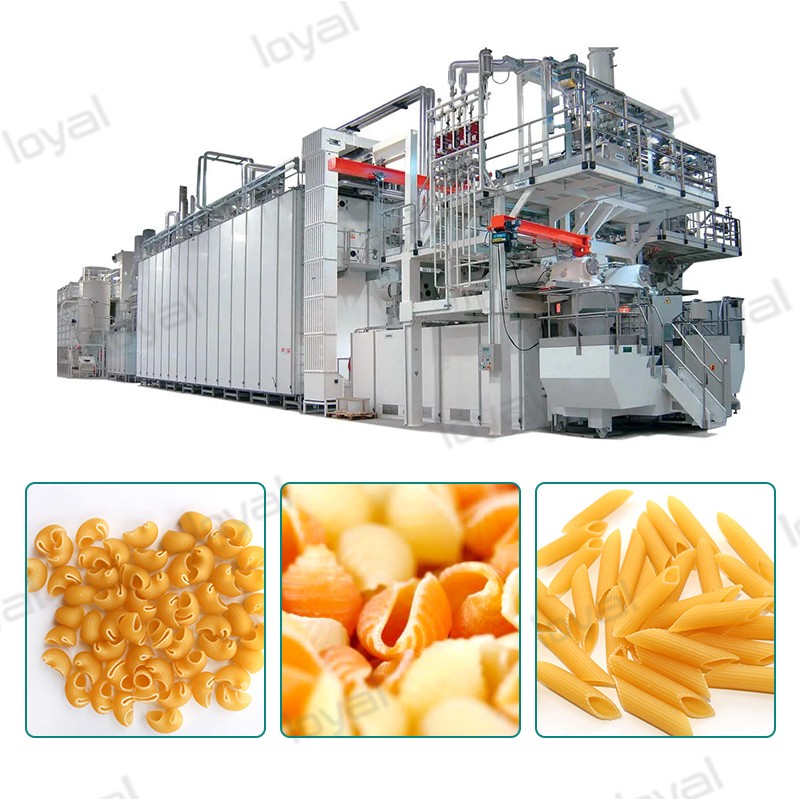

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from HEMAKS and AXOR in the production of its macaroni.In the realm of culinary excellence, pasta production holds a significant place, satisfying palates worldwide. At the forefront of this culinary revolution is the 200kg Pasta Factory Machine, a marvel that has reshaped the landscape of pasta manufacturing. This introduction sets the stage for a comprehensive exploration of how vacuum extrusion technology, embodied in the 200kg Pasta Factory Machine, has become synonymous with precision in motion within the pasta production industry.

The 200kg Pasta Factory Machine: Technological Marvel

Features and Capabilities:

The 200kg Pasta Factory Machine stands as a technological marvel, seamlessly blending efficiency and precision. Its advanced features, including automated mixing, extrusion, and drying processes, ensure a streamlined and controlled pasta production environment.

Precision and Efficiency:

Boldly utilizing vacuum extrusion technology, the machine achieves unparalleled precision in shaping pasta. The result is a consistent product with the desired texture, taste, and visual appeal. This precision significantly enhances the efficiency of the pasta manufacturing process.

Impact on the Industry:

Experts in the field acknowledge the transformative impact of the 200kg Pasta Factory Machine on the pasta manufacturing industry. Renowned authorities state, "This technological marvel has not only increased production efficiency but has also set a new standard for the quality of pasta products."

Vacuum Extrusion Technology: Driving Precision

Fundamentals of Vacuum Extrusion:

Delving into the core of vacuum extrusion technology, we uncover how it revolutionizes pasta production. The process involves the creation of a vacuum environment, allowing for precise control over the extrusion of pasta dough. This technology ensures that each strand of pasta maintains uniformity in shape and texture.

Enhancing Shaping and Quality:

Boldly employing vacuum extrusion, the 200kg Pasta Factory Machine enhances the shaping and quality of pasta products. The controlled environment minimizes variations, resulting in pasta with a superior taste and texture. Industry leaders emphasize, "Vacuum extrusion is the driving force behind the unparalleled precision achieved in modern pasta manufacturing."

Operational Advantages of the 200kg Pasta Factory Machine

Streamlining Production:

The 200kg Pasta Factory Machine brings operational advantages that streamline the pasta production process. Automated features reduce manual labor, increasing overall efficiency. This results in higher output and consistent product quality.

Real-world Examples:

Real-world examples and case studies highlight the success of pasta manufacturers who have embraced the 200kg Pasta Factory Machine. Brands such as De Cecco, Great Value, Faella, and Pastificio Di Martino have reaped the benefits, producing pasta that meets the highest standards of excellence.

Innovations in Pasta Manufacturing: A Glimpse into the Future

Anticipating Advancements:

Looking ahead, we anticipate continuous advancements and innovations in pasta manufacturing technology. The 200kg Pasta Factory Machine serves as a catalyst for future enhancements, fostering a dynamic landscape in the industry.

Evolving Processes:

Exploring potential enhancements to the 200kg Pasta Factory Machine and vacuum extrusion processes, we foresee an evolution towards even greater efficiency, sustainability, and customization. The industry is on the cusp of exciting developments that will shape the future of pasta production.

Conclusion

In conclusion, the exploration of Precision in Motion: Unveiling the 200kg Pasta Factory Machine with Vacuum Extrusion Technology has unveiled a transformative journey within the pasta manufacturing landscape. As we reflect on the features, capabilities, and impact of the 200kg Pasta Factory Machine, it becomes evident that precision and efficiency are no longer aspirations but the standard in modern pasta production.

The success stories of esteemed brands like De Cecco, Great Value, Faella, and Pastificio Di Martino attest to the machine's effectiveness in achieving unparalleled quality. Looking forward, the innovations in pasta manufacturing technology, driven by the 200kg Pasta Factory Machine, promise an exciting future characterized by sustainability, efficiency, and a diverse range of pasta products.

In essence, the 200kg Pasta Factory Machine, with its integration of vacuum extrusion technology, stands as a beacon of excellence in the world of food machinery, reshaping the pasta industry and paving the way for a future where precision in motion defines the art of pasta production.

FAQs: Common Questions about Pasta Factory Machine

Q1: How does the 200kg Pasta Factory Machine enhance precision in pasta production?

A: The machine utilizes vacuum extrusion technology to create a controlled environment, ensuring uniform shaping and quality in every strand of pasta.

Q2: Which pasta brands have successfully adopted the 200kg Pasta Factory Machine?

A: Notable brands such as De Cecco, Great Value, Faella, and Pastificio Di Martino have embraced the machine, achieving success in producing high-quality pasta.

Q3: What future innovations can we expect in pasta manufacturing technology?

A: Anticipated advancements include greater efficiency, sustainability, and customization, shaping the future landscape of pasta production.

Q4: How does vacuum extrusion contribute to the efficiency of the pasta manufacturing process?

A: Vacuum extrusion ensures precise control over the extrusion of pasta dough, minimizing variations and enhancing the overall efficiency of the manufacturing process.

Q5: Can the 200kg Pasta Factory Machine be customized for different pasta shapes?

A: Yes, the machine's advanced features allow for customization, enabling pasta manufacturers to produce a variety of shapes to meet consumer demands.

Q6: What sets the 200kg Pasta Factory Machine apart from traditional pasta-making methods?

A: The machine's automated processes and integration of vacuum extrusion technology set it apart by offering a higher level of precision, efficiency, and consistency compared to traditional methods.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Combined Pasta Machine

Combined Pasta Machine Macaroni Pasta Production Line

Macaroni Pasta Production Line Spaghetti Pasta Production Line

Spaghetti Pasta Production Line PRECOOKED PASTA PRODUCTION LINE

PRECOOKED PASTA PRODUCTION LINE