- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Revolutionizing Pasta Production: Exploring Advanced Macaroni Manufacturing Processes

Revolutionizing Pasta Production: Exploring Advanced Macaroni Manufacturing Processes

Revolutionizing Pasta Production: Exploring Advanced Macaroni Manufacturing Processes

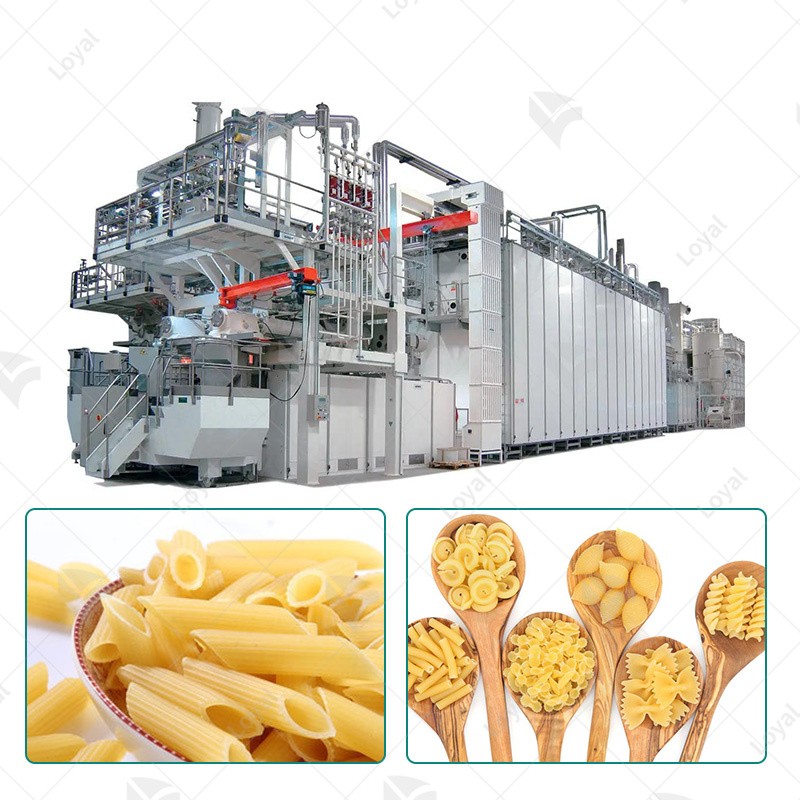

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Germany's Buhler and Italy's GEA in the production of its macaroni.In the realm of food machinery, the process of macaroni manufacturing has undergone a remarkable transformation, embracing cutting-edge technologies and innovative methodologies. This article delves into the evolution of pasta processing equipment, exploring key components, efficiency gains, and future innovations. As we navigate through the intricacies of advanced macaroni production, we will also examine success stories, challenges faced, and solutions implemented in this dynamic industry.

Evolution of Macaroni Manufacturing Processes

The history of macaroni manufacturing processes is a fascinating journey, witnessing significant advancements over the years. From traditional hand-crafted methods to the sophisticated machinery of today, the evolution reflects a commitment to enhancing production efficiency and product quality. As we trace this evolution, key milestones will be highlighted, providing a comprehensive understanding of the industry's progression.

Key Components of Advanced Macaroni Manufacturing

Modern macaroni manufacturing involves a synergy of advanced components, each playing a crucial role in the overall process. The integration of state-of-the-art extruders, drying systems, and quality control measures ensures precision and consistency in macaroni production. Throughout this section, the focus will be on these key components, shedding light on their functions and contributions to the advanced manufacturing landscape.

Efficiency and Precision in Modern Macaroni Production

Efficiency and precision are paramount in the contemporary macaroni manufacturing landscape. Cutting-edge technologies, such as automated shaping and computerized control systems, have revolutionized the way macaroni is produced. This section explores how these advancements have not only increased production speed but also elevated the precision and uniformity of macaroni products, meeting the highest quality standards.

Innovations Shaping the Future

The future of macaroni manufacturing holds exciting possibilities with ongoing innovations. This section discusses emerging trends, including smart manufacturing, sustainable practices, and the incorporation of artificial intelligence. As the industry continues to evolve, staying at the forefront of these innovations will be instrumental in ensuring sustained growth and competitiveness.

Case Studies: Success Stories in Advanced Macaroni Manufacturing

Examining real-world applications, this section presents case studies of renowned macaroni brands that have successfully embraced advanced manufacturing processes. Brands like Barilla, De Cecco, Creamette, San Giorgio, and Great Value serve as exemplars of how adopting cutting-edge technology can lead to heightened efficiency, improved product quality, and increased market share.

Challenges and Solutions in Implementing Advanced Processes

While the benefits of advanced macaroni manufacturing are evident, challenges in implementation cannot be ignored. This section addresses common challenges faced by manufacturers and explores viable solutions. Insights from industry experts and authorities will be incorporated to provide a comprehensive perspective on navigating the complexities of adopting advanced processes.

Conclusion

In conclusion, the exploration of advanced macaroni manufacturing processes highlights a dynamic industry committed to continuous improvement. From historical evolution to present innovations, the journey has been marked by efficiency gains, precision, and a vision for the future. As the industry moves forward, the integration of technology and adherence to quality standards will be pivotal for sustained success.

FAQs: Common Questions about Macaroni Manufacturing Processes

Q1: What raw materials are commonly used in macaroni manufacturing?

A1: The primary raw materials for macaroni manufacturing include durum wheat semolina, water, and occasionally, other ingredients like eggs. Durum wheat semolina, known for its high protein content and gluten strength, is a key factor in producing the desired texture and quality in macaroni.

Q2: How long does the macaroni manufacturing process typically take?

A2: The duration of the macaroni manufacturing process varies but generally involves several stages, including mixing, extrusion, drying, and packaging. The entire process can take anywhere from a few hours to a day, depending on the scale of production and the specific manufacturing methods employed.

Q3: What quality control measures are implemented in advanced macaroni manufacturing?

A3: Advanced macaroni manufacturing processes incorporate rigorous quality control measures to ensure consistency and adherence to high standards. Automated systems, sensor technologies, and real-time monitoring are employed to check factors such as shape, size, color, and texture throughout the production line, guaranteeing a uniform and premium product.

Q4: How do advanced macaroni manufacturing processes contribute to sustainability?

A4: Many advanced macaroni manufacturing facilities prioritize sustainability by implementing eco-friendly practices. This includes optimizing energy usage, reducing water consumption, and exploring packaging solutions that minimize environmental impact. Sustainable practices not only benefit the planet but also align with consumer preferences for environmentally conscious products.

Q5: Can you elaborate on the role of artificial intelligence in modern macaroni manufacturing?

A5: Artificial intelligence (AI) plays a significant role in modern macaroni manufacturing by enhancing automation and decision-making processes. AI algorithms can optimize production parameters, monitor equipment performance, and predict maintenance needs, contributing to increased efficiency and reduced downtime.

Q6: How have leading brands like Barilla and De Cecco embraced advanced manufacturing processes?

A6: Brands like Barilla and De Cecco have been at the forefront of adopting advanced manufacturing processes. They invest in state-of-the-art equipment, automation, and quality control measures to ensure the consistent production of high-quality macaroni. These brands serve as industry benchmarks for leveraging technology to achieve operational excellence.

Q7: What are the common challenges faced by manufacturers in implementing advanced macaroni manufacturing processes?

A7: Challenges in implementing advanced processes may include initial capital investment, workforce training, and the need for adapting to new technologies. However, the long-term benefits, such as increased efficiency and product quality, often outweigh these challenges. Manufacturers can overcome these hurdles with strategic planning and a phased approach to implementation.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Instant Pasta Production Line

Instant Pasta Production Line INSTANT PASTA CUP PRODUCTION LINE

INSTANT PASTA CUP PRODUCTION LINE Macaroni Pasta Production Line

Macaroni Pasta Production Line Long-Cut Pasta Production Line

Long-Cut Pasta Production Line