- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Sustainable Excellence: Advancing Macaroni Pasta Production with European-Origin Vacuum Extrusion

Sustainable Excellence: Advancing Macaroni Pasta Production with European-Origin Vacuum Extrusion

Sustainable Excellence: Advancing Macaroni Pasta Production with European-Origin Vacuum Extrusion

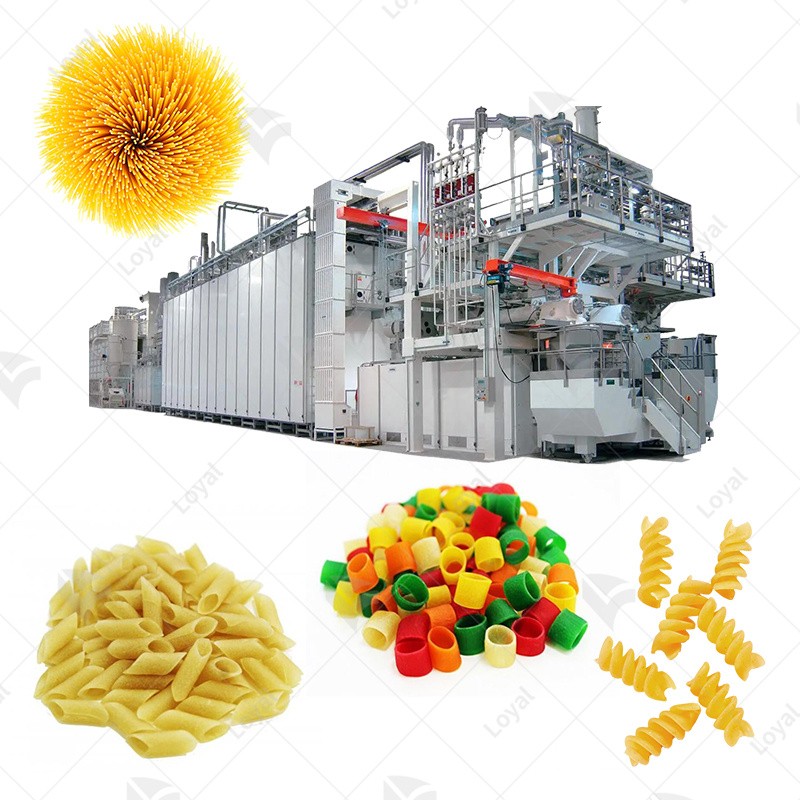

In the dynamic landscape of the food industry, sustainability has emerged as a pivotal factor driving innovation and progress. This article delves into the transformative realm of macaroni pasta production, specifically focusing on the sustainable excellence achieved through the integration of the Macaroni Pasta Production Line and European-Origin Vacuum Extrusion technology.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Germany's Buhler and Gidamak in the production of its macaroni.

Understanding European-Origin Vacuum Extrusion

European-Origin Vacuum Extrusion stands at the forefront of technological innovation in macaroni pasta production. With its roots in precision engineering, this technology not only ensures efficiency but also boasts sustainable features. The use of vacuum extrusion enhances precision, consistency, and the overall sustainability of the macaroni production process.

The Evolution of Macaroni Pasta Production Line

The journey of macaroni pasta production lines has witnessed a remarkable evolution. Advancements and innovations have been pivotal in steering the industry toward sustainability. This section explores how technology has played a crucial role in transforming macaroni pasta production into an environmentally conscious and resource-efficient process.

Components of Sustainable Macaroni Pasta Production

An in-depth analysis of the components comprising a sustainable Macaroni Pasta Production Line sheds light on the industry's commitment to reducing environmental impact. Each component contributes to energy efficiency, waste reduction, and overall sustainability. Examples of sustainable features implemented by leading manufacturers showcase the industry's dedication to responsible practices.

Case Studies: Success Stories in Sustainable Macaroni Production

Real-world case studies highlight companies that have successfully embraced sustainable practices in macaroni pasta production. Through these success stories, we gain insights into the economic benefits, reduced environmental footprint, and the positive impact on market competitiveness achieved by adopting sustainable methods.

Challenges and Solutions in Sustainable Macaroni Production

Despite progress, the industry faces challenges in fully adopting sustainable practices. This section addresses these challenges and explores innovative solutions and technologies that overcome obstacles. Collaboration and partnerships within the industry are also examined for their role in promoting sustainability.

Future Outlook: Advancements in Sustainable Macaroni Pasta Production

Anticipating future trends and innovations in sustainable macaroni pasta production sets the stage for continuous improvement. Ongoing research and development efforts aim to enhance sustainability, catering to changing consumer expectations and environmental considerations that will shape the industry's future.

Conclusion

In summary, the exploration of sustainable excellence in macaroni pasta production showcases the pivotal role played by the Macaroni Pasta Production Line and European-Origin Vacuum Extrusion. As the industry progresses towards a more sustainable future, the importance of responsible practices becomes paramount, ensuring a harmonious balance between production efficiency and environmental stewardship.

FAQs: Common Questions about Macaroni Pasta Production Line Sustainability

1. What makes a Macaroni Pasta Production Line sustainable?

Answer: A sustainable Macaroni Pasta Production Line incorporates energy-efficient machinery, waste reduction measures, and eco-friendly materials. It focuses on minimizing environmental impact throughout the production process.

2. How does European-Origin Vacuum Extrusion contribute to sustainability?

Answer: European-Origin Vacuum Extrusion is known for its energy efficiency and precision in pasta shaping. By reducing energy consumption and optimizing the production process, it aligns with sustainability goals in macaroni pasta manufacturing.

3. Are sustainable Macaroni Pasta Production Lines more expensive to set up?

Answer: Initially, there might be a slightly higher investment, but sustainable practices often lead to long-term cost savings. Energy-efficient equipment and reduced waste contribute to operational efficiency and economic benefits.

4. Can small-scale pasta manufacturers adopt sustainable practices?

Answer: Yes, sustainable practices are scalable. Even small-scale pasta manufacturers can adopt energy-efficient machinery, implement waste reduction strategies, and source eco-friendly materials to enhance sustainability.

5. Do sustainable Macaroni Pasta Production Lines compromise on product quality?

Answer: No, sustainable practices are designed to enhance product quality. By focusing on precision and efficiency, sustainable production lines often result in better-quality macaroni pasta that meets consumer expectations.

6. How can consumers identify sustainably produced macaroni products?

Answer: Look for certifications, such as eco-labels or sustainability badges, on product packaging. Brands transparent about their sustainability practices often provide information on their websites about sourcing, manufacturing, and environmental commitments.

7. Are there regulations governing sustainability in macaroni pasta production?

Answer: While specific regulations may vary, the food industry often adheres to general environmental standards. Additionally, certifications like ISO 14001 or participation in sustainability initiatives demonstrate a commitment to meeting or exceeding regulatory requirements.

8. What role do consumers play in promoting sustainability in the macaroni pasta industry?

Answer: Consumers play a crucial role by making informed choices, supporting brands with sustainable practices, and encouraging industry transparency. Demand for sustainable products drives manufacturers to adopt eco-friendly practices.

9. How can manufacturers continually improve sustainability in their production lines?

Answer: Continuous improvement involves regular assessments, adopting new technologies, and staying updated on sustainable practices. Collaboration with industry experts and participation in sustainability networks also contribute to ongoing improvement.

10. What are the environmental benefits of sustainable macaroni pasta production?

Answer: Sustainable production reduces energy consumption, minimizes waste, and often involves responsible sourcing. These practices contribute to lower carbon footprints, conservation of resources, and a positive environmental impact.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Pasta Processing Equipment

Pasta Processing Equipment INSTANT PASTA CUP PRODUCTION LINE

INSTANT PASTA CUP PRODUCTION LINE Macaroni Pasta Production Line

Macaroni Pasta Production Line Spaghetti Pasta Production Line

Spaghetti Pasta Production Line