- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Unveiling a Game-Changer: Fully Automatic Processes as the Shortcut for Manufacturing Excellence in Pasta Production

Unveiling a Game-Changer: Fully Automatic Processes as the Shortcut for Manufacturing Excellence in Pasta Production

Unveiling a Game-Changer: Fully Automatic Processes as the Shortcut for Manufacturing Excellence in Pasta Production

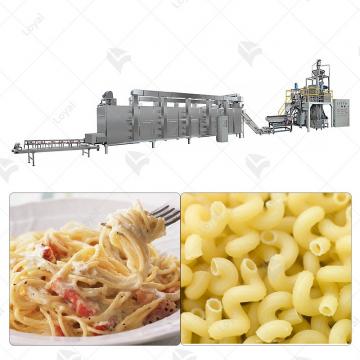

Pasta production, deeply rooted in culinary traditions, has witnessed a transformative shift propelled by technological advancements. The dynamics of pasta production have evolved from manual craftsmanship to a sophisticated interplay of machinery and innovation.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Capitanio and HEMAKS in the production of its short-cut pasta production line.

The significance of fully automatic processes in pasta production cannot be overstated. As we delve into this exploration, it becomes evident that these processes are not merely technological enhancements but a revolutionary shortcut for achieving manufacturing excellence in the pasta industry.

Th e Evolution of Pasta Manufacturing Efficiency

e Evolution of Pasta Manufacturing Efficiency

Historically, pasta manufacturing was a labor-intensive endeavor, relying on skilled hands and traditional methods. The journey towards efficiency began with the Industrial Revolution, marking a paradigm shift in how pasta was produced. The need for a more streamlined approach laid the groundwork for the evolution we witness today.

The emergence of fully automatic processes signifies a pivotal moment in the history of pasta manufacturing. From the clatter of manual machinery to the seamless operation of automated systems, efficiency has become the driving force behind the adoption of these advanced processes.

The Game-Changing Features of Fully Automatic Systems

Fully automatic systems are characterized by their ability to oversee the entire pasta production process without human intervention. The components of these systems, including programmable controls and real-time monitoring, form a powerful synergy that defines the game-changing nature of this technology.

Boldly stepping into an era of unparalleled efficiency, fully automatic processes ensure precision in every aspect of pasta production. The ability to consistently deliver high-quality products at scale sets these systems apart as true game-changers in the pursuit of manufacturing excellence.

Energy Conservation in Fully Automatic Pasta Production

Energy-efficient technologies integrated into fully automatic pasta production systems contribute to sustainability and cost-effectiveness. These technologies, ranging from smart heating mechanisms to energy recovery systems, underscore the commitment to environmental responsibility.

The shortcut for manufacturing excellence extends beyond efficiency; it encompasses sustainability and resource optimization. Fully automatic pasta production not only streamlines processes but does so in a manner that minimizes environmental impact and optimizes resource utilization.

Case Studies: Success Stories in Pasta Production Excellence

Leading the charge in embracing fully automatic processes are industry-renowned brands like DeLallo, Faella, Pastificio Di Martino, and Rao's Homemade. These companies stand as living testaments to the success achievable through the integration of advanced pasta production technologies.

Examining the experiences of these trailblazing companies offers valuable lessons and best practices for others in the industry. From increased production output to enhanced product consistency, the journey of these companies serves as a guide for those considering the shortcut for manufacturing excellence.

Future Prospects: Innovations in Fully Automatic Pasta Production

The future of fully automatic pasta production holds exciting prospects with emerging technologies such as artificial intelligence and data analytics. These innovations are set to redefine efficiency, offering a glimpse into the next phase of manufacturing excellence.

The journey does not end with current advancements. Continuous improvement and adaptation will be key as the industry evolves. Staying at the forefront of technological innovations ensures that fully automatic processes remain at the pinnacle of efficiency in pasta production.

Conclusion

As we look forward, the commitment to continuous improvement and adaptation ensures that fully automatic processes will remain at the forefront of efficiency and innovation. Embracing this shortcut for manufacturing excellence is not just about meeting industry standards; it is a commitment to exceeding expectations and securing a sustainable future for pasta production.

In the ever-evolving world of pasta manufacturing, the shortcut for excellence is not just a technological advancement; it is the key to unlocking a future where efficiency, sustainability, and innovation coalesce to redefine the standards of the industry.

FAQs: Frequently Asked Questions about Manufacturing Excellence in Pasta Production

1. What distinguishes fully automatic processes as a game-changer in pasta production?

Fully automatic processes revolutionize pasta production by streamlining the entire manufacturing process, from dough preparation to packaging. The integration of programmable controls and real-time monitoring ensures precision, consistency, and high efficiency, setting it apart as a transformative game-changer.

2. How do energy-efficient technologies contribute to sustainability in fully automatic pasta production?

Energy-efficient technologies play a crucial role in sustainability by minimizing energy consumption and reducing the overall environmental impact. The incorporation of smart heating mechanisms and energy recovery systems exemplifies the commitment to responsible and eco-friendly pasta manufacturing.

3. Can smaller pasta manufacturers benefit from fully automatic processes?

Absolutely. While larger brands like DeLallo, Faella, Pastificio Di Martino, and Rao's Homemade have embraced fully automatic processes, scalable solutions allow smaller manufacturers to adopt this manufacturing shortcut according to their production capacity and goals.

4. Are there challenges associated with adopting fully automatic systems in pasta production?

While the benefits are substantial, challenges may include initial investment costs and the need for staff training. However, the long-term advantages such as increased production efficiency, reduced operational costs, and improved product quality often outweigh these challenges.

5. What innovations can we expect in the future of fully automatic pasta production?

The future promises exciting innovations in fully automatic pasta production, with emerging technologies like artificial intelligence and data analytics leading the way. Predictive maintenance, adaptive processing, and further advancements in energy efficiency are on the horizon, shaping the next phase of manufacturing excellence

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Dry Pasta Production Line

Dry Pasta Production Line Short-Cut Pasta Production Line

Short-Cut Pasta Production Line PRECOOKED PASTA PRODUCTION LINE

PRECOOKED PASTA PRODUCTION LINE Macaroni Pasta Production Line

Macaroni Pasta Production Line