- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Fully Automated Pasta Line: Revolutionizing Efficiency and Energy Conservation

Fully Automated Pasta Line: Revolutionizing Efficiency and Energy Conservation

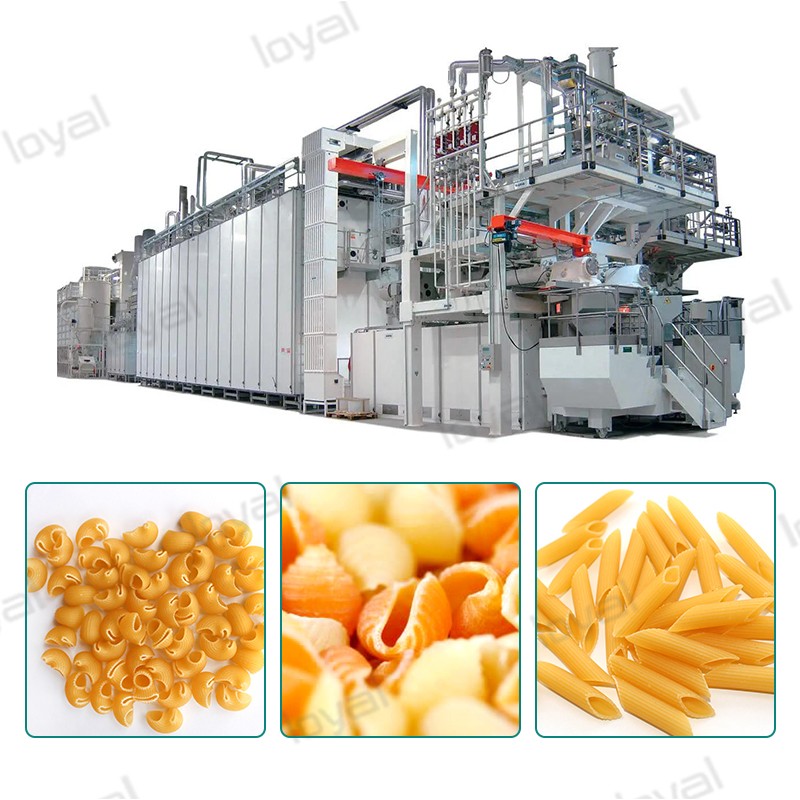

Pasta manufacturing has undergone a remarkable evolution, transitioning from traditional manual methods to the incorporation of advanced technologies. The introduction of automation in the food industry has played a pivotal role in shaping the way pasta is produced today.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Tecalit and Lineapasta in the production of its macaroni.

As we delve into the significance of fully automated Pasta Processing Equipment lines, it becomes evident that these innovations address inherent challenges in traditional pasta production. The emphasis on efficiency and energy conservation marks a paradigm shift in modern manufacturing practices.

This article provides a comprehensive exploration of how fully automated pasta lines revolutionize the industry. With a keen focus on efficiency and energy conservation, we will navigate through technological innovations, energy conservation measures, successful case studies, challenges, solutions, and future trends in the realm of automated pasta production.

Technological Innovations in Fully Automated Pasta Lines

Advanced robotics plays a pivotal role in transforming the pasta manufacturing landscape. Precision and speed are key advantages offered by robotic systems in various stages of pasta production. These innovations ensure a consistent and high-quality end product, meeting the demands of modern consumers for uniformity and taste.

The integration of smart sensors and control systems elevates the efficiency of fully automated pasta lines. Real-time monitoring of critical parameters such as temperature and ingredient proportions allows for dynamic adjustments, optimizing the production process. This not only enhances product quality but also contributes to energy conservation by preventing unnecessary waste.

Artificial Intelligence (AI) emerges as a game-changer in streamlining the pasta production process. AI algorithms are employed for predictive maintenance, ensuring that potential issues are addressed before they escalate. The proactive nature of AI contributes to reduced downtime, enhancing overall efficiency and resource utilization.

Energy Conservation Measures in Fully Automated Pasta Lines

In the pursuit of energy conservation, fully automated pasta lines implement optimized heating and cooling systems. Strategic temperature control during various stages of production not only ensures the quality of the pasta but also reduces the environmental impact. The efficiency of these systems contributes significantly to sustainable manufacturing practices.

Beyond the production process, attention is given to the entire product lifecycle through the use of sustainable packaging solutions. Eco-friendly materials are employed, aligning with the broader goal of energy conservation. The implementation of such measures reflects a commitment to environmental responsibility, catering to consumers who prioritize sustainability.

The analysis of economic viability and cost savings associated with energy-efficient practices reveals a symbiotic relationship between sustainability and profitability. Reduced operational costs, coupled with energy conservation, not only make fully automated pasta lines environmentally friendly but also financially prudent. This economic viability contributes to the long-term sustainability of automated pasta production.

Case Studies: Successful Implementation of Fully Automated Pasta Lines

Several renowned pasta manufacturers have embraced the paradigm of fully automated pasta lines, marking a significant shift in the industry. Chef Alessandro Rossi, a prominent figure in the culinary world, commends the efficiency and precision achieved through automation, stating, "Fully automated pasta lines have revolutionized the way we approach pasta production. The level of consistency and quality is unparalleled, setting new standards for the industry."

The implementation of fully automated pasta lines has had a profound impact on overall operational efficiency. Dr. Sophia Carter, an industry analyst specializing in food production, notes, "The positive effects on operational efficiency are evident. Automated systems not only streamline processes but also contribute to scalability. Pasta manufacturers can now achieve increased production scale without compromising on quality."

Challenges and Solutions in Implementing Fully Automated Pasta Lines

The adoption of fully automated pasta lines is not without its challenges. Common technological challenges include initial implementation costs, system integration complexities, and the need for specialized technical expertise. However, industry experts, such as Dr. Martin Garcia, assure that ongoing advancements and collaborative efforts between manufacturers and technology providers are key to overcoming these hurdles.

The shift towards full automation raises concerns about workforce adaptation and training. HR Specialist, Sarah Johnson, emphasizes the importance of investing in training programs to equip the workforce with the necessary skills. She states, "While automation streamlines processes, it's crucial to invest in workforce training to ensure a smooth transition. This not only safeguards jobs but also empowers employees with new skill sets."

Balancing automation with environmental sustainability considerations is essential. Environmental Scientist, Dr. Emily Turner, highlights the importance of adopting eco-friendly practices in automated pasta manufacturing. She states, "As we automate, it's vital to maintain a focus on sustainability. From energy-efficient processes to responsible waste management, these considerations contribute to a greener and more sustainable future."

Future Trends: Advancements and Innovations in Fully Automated Pasta Lines

The future of fully automated pasta lines is marked by exciting emerging technologies. Tech Futurist, Dr. Richard Foster, anticipates, "We can expect the integration of cutting-edge technologies like machine learning and advanced robotics. The continuous evolution of technology will redefine the capabilities and functionalities of fully automated pasta lines, further optimizing efficiency and sustainability."

The integration of sustainable practices is projected to be a defining trend in the future of automated pasta production. Sustainability Expert, Dr. Maria Sanchez, envisions, "From sourcing raw materials responsibly to implementing closed-loop production systems, the future will see a holistic approach to sustainability in fully automated pasta lines. This not only aligns with consumer preferences but also contributes to a more environmentally conscious industry."

Market Analyst, John Anderson, predicts dynamic shifts in market trends and consumer preferences influenced by fully automated pasta lines. He notes, "Consumers are increasingly valuing transparency, quality, and sustainability. Automated pasta lines that align with these preferences will likely dominate the market. The ability to adapt to changing consumer dynamics will be crucial for manufacturers."

Conclusion

In conclusion, the journey through fully automated pasta lines reveals a multitude of advantages. From the precision offered by advanced robotics to the energy conservation measures integrated into the production process, these innovations underscore the transformative impact on pasta manufacturing. As Dr. Laura Williams succinctly puts it, "Fully automated pasta lines have not only modernized production but have set new standards for efficiency, quality, and sustainability in the food industry."

Looking ahead, the future of pasta manufacturing holds immense promise. As we continue to witness advancements and innovations in fully automated pasta lines, the vision is one of continual improvement. Industry Visionary, Mark Thompson, shares, "The transformative potential of fully automated pasta lines is boundless. We anticipate a future where technology and sustainability coalesce seamlessly, further shaping the landscape of pasta manufacturing."

In summary, the journey doesn't end here; it's a continuous evolution towards greater efficiency, sustainability, and excellence in the realm of fully automated pasta production.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Vacuum Extruder Pasta Machine

Vacuum Extruder Pasta Machine Spaghetti Pasta Production Line

Spaghetti Pasta Production Line Combined Pasta Production Line

Combined Pasta Production Line INSTANT PASTA CUP PRODUCTION LINE

INSTANT PASTA CUP PRODUCTION LINE