- Shandong Loyal Industrial Co.,Ltd.

- SHORT-CUT PASTA PRODUCTION LINE LONG-CUT PASTA PRODUCTION LINE INSTANT PASTA PRODUCTION LINE

Home> Application> Fully Automated Macaroni Extruder: Revolutionizing Pasta Production

Fully Automated Macaroni Extruder: Revolutionizing Pasta Production

Introduction

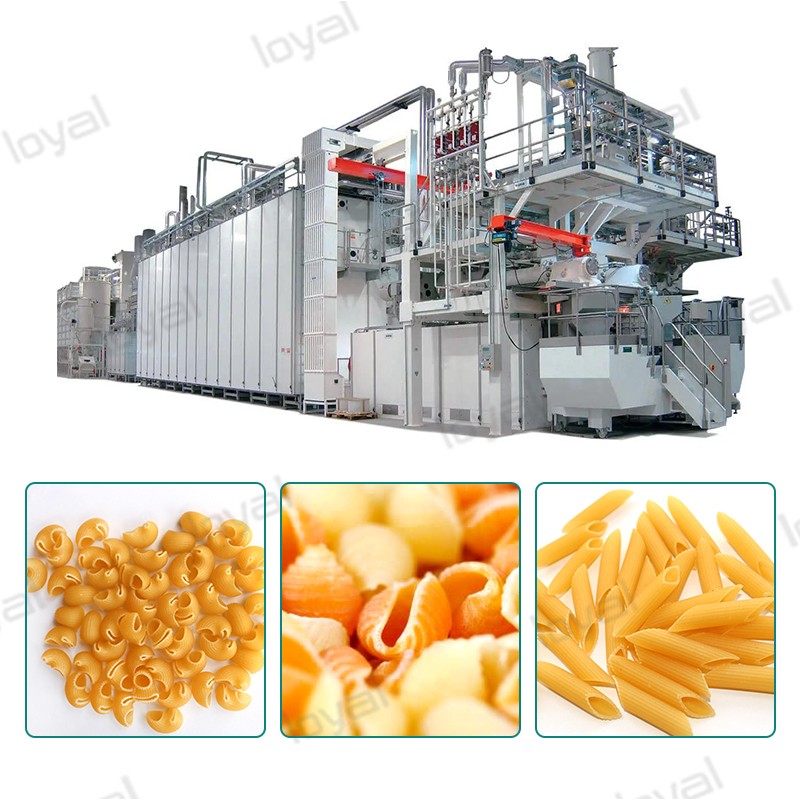

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Germany's Buhler and Italy's GEA in the production of its macaroni.Traditional pasta production has long relied on manual labor and intricate processes, but the ever-growing demand for efficiency and consistency has paved the way for innovation.The pasta industry is evolving, and to meet the demands of a dynamic market, innovation is imperative. The need for efficient, precise, and sustainable manufacturing processes has become a driving force in revolutionizing pasta production.At the forefront of this revolution is the Fully Automated Macaroni Extruder. This cutting-edge technology represents a paradigm shift, offering a glimpse into a future where pasta production is characterized by unmatched efficiency and precision.

Unveiling the Technology Behind Fully Automated Macaroni Extruders

The evolution of macaroni extrusion technology has been marked by a continuous quest for perfection. From traditional extruders to the state-of-the-art fully automated systems, the journey has been shaped by advancements in engineering and materials.

Fully automated macaroni extruders leverage robotics, artificial intelligence, and advanced sensors to enhance every aspect of the pasta production process. This level of automation ensures consistency, speed, and precision, setting new standards for efficiency.

Bold innovations define the macaroni extruder revolution. The integration of smart controls, real-time monitoring, and adaptive processing capabilities distinguishes these machines, promising a new era in pasta manufacturing.

Advantages of Fully Automated Macaroni Extruders

Bold, precise shapes define exceptional pasta, and the fully automated macaroni extruder delivers just that. The precision in shaping ensures a consistent product, meeting the highest standards of culinary aesthetics.

In the fast-paced world of food production, time is of the essence. Fully automated macaroni extruders excel in speed and throughput, meeting the demands of high-volume manufacturing without compromising on quality.

Automation isn't just about speed; it's about smart resource utilization. These extruders optimize ingredient usage, minimize waste, and contribute to a more sustainable and cost-effective pasta production process.

Implementation and Integration

Implementing fully automated macaroni extruders requires a strategic approach. Adapting existing production lines or integrating these systems into new facilities demands careful planning and collaboration with experienced manufacturers.

As technology takes center stage, training personnel becomes a crucial aspect. Skilled operators and maintenance staff are essential for the seamless operation and upkeep of fully automated macaroni extrusion systems.

Challenges in integration may arise, from initial investment concerns to operational adjustments. Addressing these challenges involves proactive problem-solving and a commitment to realizing the long-term benefits of automation.

Case Studies: Success Stories in Pasta Production

Esteemed brands such as Barilla, De Cecco, Creamette, San Giorgio, and Great Value have embraced fully automated macaroni extruders. Their success stories underscore the transformative impact on production efficiency, product quality, and overall competitiveness.

Exploring real-world examples, the implementation of fully automated macaroni extruders has demonstrated tangible reductions in production costs. Simultaneously, the quality of the pasta produced has reached new heights, setting a benchmark for the industry.

The experiences of early adopters offer valuable lessons. From initial challenges to long-term benefits, understanding the journey of those who implemented automated technologies provides insights for manufacturers considering a similar transition.

Future Prospects and Innovations

The future promises continuous improvements in macaroni extruder technology. Ongoing research and development efforts focus on refining automation algorithms, enhancing energy efficiency, and introducing new materials for even more diverse pasta shapes.

Anticipated innovations include the integration of machine learning for adaptive processing, further reducing production variability. Technological advancements may also lead to the development of compact, modular extruders that cater to varying production scales.

Automation will play a pivotal role in shaping the future of pasta production. As the industry leans towards sustainable practices, fully automated macaroni extruders will be at the forefront, contributing to resource efficiency, waste reduction, and overall sustainability.

Conclusion

In summary, fully automated macaroni extruders have redefined pasta production. The precision, speed, and resource efficiency they bring to the table mark a significant departure from traditional methods, setting new standards for the entire industry.

The implications for the pasta industry are profound. As more manufacturers adopt fully automated systems, the landscape will witness increased efficiency, reduced costs, and a heightened focus on sustainability—a collective leap into a more advanced era of pasta manufacturing.

The revolutionizing potential of automation in pasta production is not just a technological advancement; it's a transformative force. It signifies a commitment to excellence, innovation, and sustainability. As we look ahead, the influence of fully automated macaroni extruders will continue to resonate, ensuring a future where pasta production is efficient, precise, and environmentally conscious.

FAQs: Addressing Common Questions about Macaroni Extruders

1. What are the key considerations when selecting a fully automated macaroni extruder?

A3: Selecting a fully automated macaroni extruder involves evaluating factors such as production capacity, customization options, ease of maintenance, and compatibility with existing production lines. Conducting a thorough assessment ensures a tailored fit for specific manufacturing needs.

2. How do fully automated macaroni extruders contribute to sustainability?

A4: Fully automated macaroni extruders contribute to sustainability through precise ingredient utilization, reduced waste, and energy-efficient operations. Their streamlined processes align with eco-friendly practices, supporting the industry's shift towards more sustainable manufacturing.

3. Can fully automated macaroni extruders accommodate various pasta shapes and sizes?

A5: Yes, modern fully automated macaroni extruders are designed for versatility. With customizable settings and adaptive processing capabilities, these machines can accommodate a wide range of pasta shapes and sizes, offering flexibility to meet diverse market demands.

4. What kind of training is required for personnel operating automated macaroni extruders?

A6: Personnel operating automated macaroni extruders require training in machine operation, maintenance, and troubleshooting. Hands-on training, supplemented by educational resources provided by manufacturers, ensures operators are well-equipped to handle the complexities of these advanced systems.

5. How do automated macaroni extruders impact the job market in the pasta industry?

A7: While automation streamlines production processes, it also creates opportunities for skilled technicians and engineers specializing in machine maintenance and programming. The industry may see a shift in job roles towards more technologically oriented positions, emphasizing the importance of ongoing skill development.

Contact Us

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+86 13176674591

- Email[email protected]

- WhatsApp+86 13176674591

- WeChat13176674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

DRY PASTA PRESS MACHINE

DRY PASTA PRESS MACHINE Macaroni Pasta Production Line

Macaroni Pasta Production Line Combined Pasta Production Line

Combined Pasta Production Line Dry Pasta Production Line

Dry Pasta Production Line